The installation, service and maintenance of this equipment should be rendered by a qualified and trained service technician. Your local independently operated Culligan dealer employs trained service and maintenance personnel who are experienced in the installation, function and repair of Culligan equipment. This publication is written specifically for these individuals and is intended for their use.

We encourage Culligan users to learn about Culligan products, but we believe that product knowledge is best obtained by consulting with your Culligan dealer. Untrained individuals who use this manual assume the risk of any resulting property damage or personal injury.

WARNING! Electrical shock hazard! Prior to servicing equipment, disconnect power supply to prevent electrical shock.

NOTICE: This system is not intended for use where water is microbiologically unsafe or with water of unknown quality.

WARNING! If incorrectly installed, operated or maintained, this product can cause severe injury. Those who install, operate, or maintain this product should be trained in its proper use, warned of its dangers, and should read the entire manual before attempting to install, operate, or maintain this product.

WARNING! This device complies with part 15 of the FCC rules subject to the two following conditions: 1) This device may not cause harmful

interference, and 2) This device must accept all interference received including interference that may cause undesired operation.

This equipment complies with Part 15 of the FCC rules. Any changes or modifications not expressly approved by the manufacturer could void the user’s authority to operate the equipment. Changes or modifications not expressly approved by the party responsible for compliance could void the user’s authority to operate the equipment.

CAUTION! To reduce the risk of fire, use only No. 26 AWG or larger telecommunications line cord.

CAUTION! This product is not to be used by children or persons with reduced physical, sensory or mental capabilities, or lack of experience or knowledge, unless they have been given supervision or instruction.

CAUTION! Children should be instructed not to play with this appliance.

CAUTION! If the power cord from the transformer to the unit looks or becomes damaged, the cord and transformer should be replaced by a Culligan Service Agent or similarly qualified person in order to avoid a hazard.

Products manufactured and marketed by Culligan International Company (Culligan) and its affiliates are protected by patents issued or pending in the United States and other countries. Culligan reserves the right to change the specifications referred to in this literature at any time, without prior notice. Culligan, AquaSensor, Tripl-Hull, and SoftMinder are trademarks of Culligan International Company or its affiliates.

Culligan International Company 9399 West Higgins Road, Suite 1100 Rosemont, Illinois 60018 1-847-430-2800 www.culligan.com

This manual:

• Familiarizes the operator with the equipment

• Explains installation and setup procedures

• Provides basic programming information

• Explains the various modes of operation

• Gives specifications and troubleshooting information

READ ALSO: MORTON MOTORIZED WATER SHUTOFF VALVE USER’S MANUAL

Read this Manual First

Before you operate the Culligan High Efficiency Automatic Water Softener, read this manual to become familiar with the device and its capabilities.

Installation or maintenance done on this system by an untrained service person can cause major damage to equipment or property damage. Not adhering to the recommended service/ maintenance can cause damage to equipment or property damage.

Safe Practices

Throughout this manual there are paragraphs set off by special headings.

Notice (or Note) is used to emphasize installation, operation or maintenance information which is important, but does not present any hazard. For example,

NOTICE: The nipple must extend no more than 1 inch above the cover plate.

Caution is used when failure to follow directions could result in damage to equipment or property.

CAUTION! Disassembly while under water pressure can result in flooding.

Warning is used to indicate a hazard which could cause injury or death if ignored.

WARNING! Electrical shock hazard! Unplug the unit before removing the timer mechanism or cover plates!

The CAUTION and WARNING paragraphs are not meant to cover all possible conditions and situations that may occur. Understand that common sense, caution, and careful attention are conditions which cannot be built into the equipment. These MUST be supplied by the personnel installing, operating, or maintaining the system.

Be sure to check and follow the applicable plumbing codes and ordinances when installing this equipment. Local codes may prohibit the discharge of sanitizing or descaling solutions to drain.

Use protective clothing and proper face or eye protection equipment when handling chemicals or tools.

NOTICE: The Culligan High Efficiency Softener is not intended for use with water that is microbiologically unsafe or of unknown quality without adequate disinfection either before or after the system.

NOTE: Check with your public works department for applicable local plumbing and sanitation codes. Follow local codes if they differ from the standards used in this manual. To ensure proper and efficient operation of the Culligan High Efficiency Filter to your full satisfaction, carefully follow the instructions in this manual.

Welcome To Your New World of Better Living with Culligan Water.

The Culligan HE Water Softeners with Soft-Minder® Meter and Aqua-Sensor® sensing device are tested and certified by WQA against NSF/ANSI Standard 372, CSA B483.1, and NSF/ANSI Standard 44 for the effective reduction of hardness (calcium and magnesium),

barium, and radium 226/228, as verified and substantiated by test data.

The Culligan HE Water Softeners with Soft-Minder® Meter and Aqua-Sensor® sensing device are certified by IAPMO R&T against NSF/ANSI Standard 372, CSA B483.1, and NSF/ANSI Standard 44 for the effective reduction of hardness (calcium and magnesium), barium, and radium 226/228, as verified and substantiated by test data.

The Culligan HE Water Softeners with Soft-Minder® Meter and Aqua-Sensor® sensing device are registered for sale with the State of California and the State of Iowa.

The Culligan HE Municipal Water Softeners are tested and certified by WQA against NSF/ANSI Standard 372, CSA B483.1, and NSF/ANSI Standard 44 for the effective reduction of hardness (calcium and magnesium), and NSF/ANSI Standard 42 for the effective reduction of Chlorine Taste and Odor, as verified and substantiated by test data.

The Culligan HE Municipal Water Softeners are certified by IAPMO R&T against NSF/ ANSI Standard 372, CSA B483.1, and NSF/ANSI Standard 44 for the effective reduction of hardness (calcium and magnesium), and NSF/ANSI Standard 42 for the effective reduction of Chlorine Taste and Odor, as verified and substantiated by test data.

The Culligan HE Water Softener Outdoor Controller Enclosure complies with the UL 50/50E standards for an IP46 Enclosure Rating.

For installations in Massachusetts, the Massachusetts Plumbing Code 248 CMR shall be adhered to. Consult your licensed plumber for installation of this system. This system and its installation must comply with state and local regulations. The use of saddle valves is not permitted.

If this is your first experience having soft, conditioned water in your home, you’ll be amazed at the marvelous difference it makes. We promise that you’ll never want to be without it again.

Congratulations, too, on selecting one of the “first family” of water conditioners in the prestigious Culligan High Efficiency Water Softeners. With Culligan’s many years of knowledge and experience in water treatment, you can be confident that the model you selected has been designed and engineered to provide years of service with a minimum of care and attention.

Some localities have corrosive water. A water softener cannot correct this problem and so its written warranty disclaims liability for corrosion of plumbing lines, fixtures or appliances. If you suspect corrosion, your Culligan Dealer has equipment to control the problem.

NOTICE: Sodium Information: Water softeners using sodium chloride for regeneration add sodium to the water. Persons who are on sodium restricted diets should consider the added sodium as part of their overall sodium intake.

Serial Numbers

The control valve serial number is located on the back of the electrical enclosure.

The media tank serial number is located on the top surface of the tank.

NOTE: DO NOT remove or destroy the serial number. It must be referenced on request for warranty repair or replacement.

Specifications

Aqua-Sensor® Device or Soft-Minder® Meter—Downflow Regeneration

| Model | 9″ Model | 10″ Model | 12″ Model | 14″ Model |

| Control Valve | 1” Reinforced Thermoplastic w/ HE Circuit Boards | |||

| Overall Conditioner Ht | 56 in | 62 in | 60 in | 73 in |

| Media Tank Design | Quadra-Hull TM | |||

| Media Tank Dimensions (Dia x Ht) | 9 x 48 in | 10 x 54 in | 12 x 52 in | 14 x 65 in |

| Salt Storage Tank Dimensions (Dia x Ht) | 16 x 43 in or 18 x 43 in | 16 x 43 in or 18 x 43 in | 18 x 43 in | 24 x 42 in |

| Exchange Media, Type and Quantity | Cullex® Media,1.0 ft3 | Cullex Media, 1.5 ft3 | Cullex Media, 2.0 ft3 | Cullex Media, 3.0 ft3 |

| Underbedding, Type and Quantity | Cullsan® Underbedding, 12 lb | Cullsan Underbedding, 15 lb | Cullsan Underbedding, 20 lb | Cullsan Underbedding, 25 lb |

| Exchange Capacity @ Salt Dosage Per Recharge | 17,854 gr @ 4.0 lb | 26,781 gr @ 6.0 lb | 31,352 gr @ 7.0 lb | 51,726 gr @ 12 lb |

| 27,108 gr @ 8.0 lb | 40,662 gr @ 12.0 lb | 48,458 gr @ 16.0 lb | 75,582 gr @ 24 lb | |

| 31,736 gr @ 12.0 lb | 47,604 gr @ 18.0 lb | 59,267 gr @ 18.0 lb | 88,549 gr @ 36 lb | |

| Efficiency rated dosage1 | 4,463 gr/lb @ 4 lb salt dosage | 4,463 gr/lb @ 6 lb salt dosage | 4,479 gr/lb @ 7 lb salt dosage | 4,310 gr/lb @ 12 lb salt dosage |

| Freeboard to Media2 | 14.5 in | 14.5 in | 16 in | 25 in |

| Freeboard to Underbedding3 | 44.5 in | 47.5 in | 46 in | 59 in |

| Salt Storage Capacity | 250 lb or 375 lb | 250 lb or 375 lb | 375 lb | 600 lb |

| Rated Service Flow @ pressure Drop | 9.0 gpm @ 11 psi | 9.4 gpm @ 12 psi | 10.0 gpm @ 10 psi | 10.6 gpm @ 11 psi |

| Auxiliary Flow Rate4 | 10.8 gpm @ 15 psi | 11.0 gpm @ 15 psi | 12.6 gpm @ 15 psi | 12.8 gpm @ 15 psi |

| Total Hardness, Maximum | 75 gpg | 99 gpg | 99 gpg | 99 gpg |

| Total Iron, Maximum | 5 ppm | |||

| Hardness to Iron Ratio, Minimum | 8 gpg to 1 ppm | |||

| Operating Pressure | 20-125 psi (138–862 kPa) | |||

| Operating Pressure (Canada) | 20-90 psi (138–621 kPa) | |||

| Operating Temperature | 33-120°F (0–49°C) | |||

| Electrical Requirements | 24V/60 Hz | |||

| Electrical Power Consumption, Min/Max | 8.4 watts/21.6 watts | |||

| Drain Flow, Maximum5 | 2.5 gpm | 2.5 gpm | 3.0 gpm | 5.3 gpm |

| Recharge Time, Average6 Recharge Water | 78 minutes | 67 minutes | 62 minutes | 76 minutes |

| Consumption, Average6 | 47 gallons | 45 gallons | 67 gallons | 155 gallons |

1.The efficiency rated dosage is only valid at the stated salt dosage and is efficiency rated according to NSF/ANSI Standard 44.

2.Measured from top of media to top surface of tank threads (backwashed and drained).

3.Measured from top of underbedding to top surface of tank threads.

4.Auxiliary flow rates do not represent the maximum service flow rate used for determining the softener’s rated capacity and efficiency and

that continuous operation at these flow rates greater than the maximum service flow rate may affect capacity and efficiency performances.

5.Backwash at 120 psi.

6.10 minute backwash, 4 lb. 9” model, 6 lb. 10” model, 7 lb. 12” model, or 12 lb. 14” model salt dosage.

Culligan High Efficiency Softener—Upflow Regeneration

| Model | 9″ Model | 10″ Model |

| Control Valve | 1” Reinforced Thermoplastic with HE Circuit Board | |

| Overall Conditioner Height | 56 in | 62 in |

| Media Tank Design | Quadra-Hull TM | |

| Media Tank Dimensions (Dia x Ht) | 9 x 48 in | 10 x 54 in |

| Salt Storage Tank Dimensions (Dia x Ht) | 16″ x 43″ or 18″ x 43″ | |

| Exchange Media, Type and Quantity | Cullex® Media, 1.0 ft3 | Cullex Media, 1.5 ft3 |

| Underbedding, Type and Quantity | Cullsan® Underbedding, 12 lb | Cullsan Underbedding, 15 lb |

| Exchange Capacity @ Salt Dosage Per Recharge | 9,792 gr @ 2.0 lb | 30,081 gr @ 6.0 lb |

| 17,366 gr @ 4.0 lb | 47,726 gr @ 12.0 lb | |

| 27,306 gr @ 8.0 lb | 54,975 gr @ 18.0 lb | |

| Efficiency rated dosage1 | 4,896 gr/lb @ 2 lb salt dosage | 5,014 gr/lb @ 6 lb salt dosage |

| Proportional Brining Efficiency Rating2 | 5,760 gr/lb @ 2 lb salt dosage | 5,898 gr/lb @ 6 lb salt dosage |

| Freeboard to Media3 | 14.5 in | 14.5 in |

| Freeboard to Underbedding4 | 44.5 in | 47.5 in |

| Salt Storage Capacity | 250 lb or 375 lb | |

| Rated Service Flow @ Pressure Drop | 9.0 gpm @ 11 psi | 9.4 gpm @ 12 psi |

| Auxiliary Flow Rate5 | 10.8 gpm @ 15 psi | 11.0 gpm @ 15 psi |

| Total Hardness, Maximum | 30 gpg | |

| Total Iron, Maximum | 2 ppm | |

| Hardness to Iron Ratio, minimum | 8 gpg to 1 ppm | |

| Operating Pressure | 20-125 psi (138–862 kPa) | |

| Operating Pressure (Canada) | 20-90 psi (138–621 kPa) | |

| Operating Temperature | 33-120°F (0–49°C) | |

| Electrical Requirements | 24V/60 Hz | |

| Electrical Power Consumption, Min/Max | 8.4 watts/21.6 watts | |

| Drain Flow, Maximum6 | 2.2 gpm | 2.3 gpm |

| Recharge Time, Average7 Recharge Water | 68 minutes | 57 minutes |

| Consumption, Average7 (Evaluated by WQA and IAPMO R&T) | 33 gallons | 35 gallons |

| Consumption, Average8 (Not evaluated by WQA and IAPMO R&T) | 25.5 gallons | 27.5 gallons |

1.The efficiency rated dosage is only valid at the stated salt dosage and 5-minute backwash. It is efficiency rated according to NSF/ANSI 44.

2.The Proportional Brining Efficiency Rating assumes a 20 percent reserve capacity at the time of regeneration that is typical of what the manufacturer expects under real-world operation. Proportional brining is not measured by NSF/ANSI 44, and so this claim is not, and can not, be rated to NSF/ANSI 44.

3.Measured from top of media to top surface of tank threads. (backwashed and drained).

4.Measured from top of underbedding to top surface of tank threads.

5.Auxiliary flow rates do not represent the maximum service flow rate used for determining the softener’s rated capacity and efficiency and

that continuous operation at these flow rates greater than the maximum service flow rate may affect capacity and efficiency performances.

6.Backwash at 35 psi (830 kPa).

7.5 minute backwash, 2 lb. 9” model, 6 lb. 10” model. These values have been tested and certified by WQA and IAPMO R&T.

8.2 minute backwash, 2 lb. 9” model, 6 lb. 10” model. These values are based on the manufacturer recommended backwash time.

Culligan HE Municipal Water Softener

| Model | 9″ Model | 10″ Model | 12″ Model | 14″ Model |

| Control Valve | 1”, 5-cycle Reinforced Thermoplastic with Global Electronic (GBE) Circuit Board | |||

| Overall Conditioner Ht | 54 in | 60 in | 58in | 71 in |

| Media Tank Design | Quadra-Hull TM | |||

| Media Tank Dimensions (Dia x Ht) | 9 x 48 in | 10 x 54 in | 12 x 52 in | 14 x 65 in |

| Salt Storage Tank Dimensions (Dia x Ht) | 16 x 43 in or 18 x 43 in | 16 x 43 in or 18 x 43 in | 18 x 43 in | 24 x 42 in |

| Exchange Media, Type and Quantity | Cullex® Media,0.8 ft3 | Cullex Media, 1.0 ft3 | Cullex Media, 1.5 ft3 | Cullex Media, 2.3 ft3 |

| Carbon Media, Quantity | 6 lbs | 8 lbs | 12 lbs | 18 lbs |

| Underbedding, Type and Quantity | Cullsan® Underbedding, 12 lb | Cullsan Underbedding, 15 lb | Cullsan Underbedding, 20 lb | Cullsan Underbedding, 25 lb |

| Exchange Capacity @ Salt Dosage Per Recharge | 17,119 gr @ 4.0 lb | 21,399 gr @ 5.0 lb | 29,062 gr @ 7.0 lb | 39,118 gr @ 9.0 lb |

| 25,232 gr @ 8.0 lb | 31,540 gr @ 10.0 lb | 43,990 gr @ 18.0 lb | 59,297 gr @ 18.0 lb | |

| 27,806 gr @ 12.0 lb | 34,758 gr @ 15.0 lb | 49,343 gr @ 30.0 lb | 71,448 gr @ 28.0 lb | |

| Efficiency rated dosage1 | 4,280 gr/lb @ 4 lb salt dosage | 4,280 gr/lb @ 5 lb salt dosage | 4,152 gr/lb @ 7 lb salt dosage | 4,346 gr/lb @ 9 lb salt dosage |

| Freeboard to Media2 | 15.75 in | 19.5 in | 17.31 in | 25.89 in |

| Freeboard to Underbedding3 | 44.5 in | 47.5 in | 46 in | 59 in |

| Salt Storage Capacity | 250 lb or 375 lb | 250 lb or 375 lb | 375 lb | 650 lb |

| Rated Service Flow @ pressure Drop | 9.0 gpm @ 10 psi | 9.4 gpm @ 11 psi | 10.0 gpm @ 10 psi | 10.6 gpm @ 10 psi |

| Total Hardness, Maximum | 15 gpg | |||

| Total Iron, Maximum | 0 ppm | |||

| Color | Less Than 1 | |||

| Turbidity | Less Than 5 NTU | |||

| TOC | Less Than 0.5 PPM | |||

| Operating Pressure | 20-125 psi (138–862 kPa) | |||

| Operating Pressure (Canada) | 20-90 psi (138–621 kPa) | |||

| Operating Temperature | 33-120°F (0–49°C) | |||

| Electrical Requirements | 24V/60 Hz | |||

| Electrical Power Consumption, Min/Max | 8.4 watts/21.6 watts | |||

| Drain Flow, Maximum5 | 2.6 gpm | 2.6 gpm | 3.2 gpm | 6.2gpm |

| Recharge Time, Average6 Recharge Water | 78 minutes | 67 minutes | 62 minutes | 76 minutes |

| Consumption, Average6 | 70 gallons | 70 gallons | 97 gallons | 162 gallons |

1.The efficiency rated dosage is only valid at the stated salt dosage and is efficiency rated according to NSF/ANSI 44.

2.Measured from top of media to top surface of tank threads. (backwashed and drained).

3.Measured from top of underbedding to top surface of tank threads.

4.Backwash at 120 psi (830 kPa).

5.10 minute backwash, 4 lb. 9” model, 5 lb. 10” model, 7 lb. 12” model, or 9 lb. 14” model.

Introduction

It’s All So Easy, So Economical, So Efficient, So Enjoyable!

Kind To Skin And Complexion

Soft water will help prevent red, itchy or dry skin because there are no hardness impurities to cause soreness, no soap curd to coat the skin. Shaving is easier, smoother—either with a blade or electric shaver.

Bathing And Showering

You’ll use far less soap with conditioned water. Use your soap very sparingly—not as you did before soft water. Just a quick rinse removes all lather, leaving your skin pleasantly smooth and silky because now it’s free of sticky soap curd and film.

Saves Washing Costs. Helps Control Environmental Pollution

Soft water washes whiter and cleaner with less soap or detergent. Because the hardness impurities are removed, your soap can concentrate solely on washing. People usually find that they can reduce the amount of soap they use substantially. If you normally use a cup per wash load with hard water, try using 1/3 cup depending on the size of your wash load and the degree of soil. Different amounts are required, but

you can use less with softened water. An added bonus is the fact that your washable fabrics will last longer.

Super Hair Conditioning

Soft water is great for scalp and hair care. No insoluble deposits are formed. Hair is shinier, softer, more manageable. Reduce the amount of shampoo you have normally used.

Dishes Are A Delight

Washed by hand or in a dishwasher, glassware, dishes, and silver wash cleaner and easier. Follow your dishwasher manufacturer’s instructions. Soft water promotes sanitation because no greasy hard water film can form to collect or harbor bacteria.

Easier Housekeeping, Gleaming Fixtures

You’ll be amazed at the marvelous difference. Just a swish of the cloth, and the bathtub or shower and fixtures are clean and sparkling. Imagine, no scouring! No hard water scum to cause rings, streaks, spots, and stains. To keep their gleaming luster, simply wipe fixtures with a towel after use. Formica, tile, walls, floors, woodwork surfaces clean easier, stay clean longer. You’ll save on cleaning aids and save on time.

Saves Water-Heating Energy, Helps Water-Using Appliances

Soft water reduces the formation of rock-like hard water scale that encrusts water heaters, hot water pipes, shower heads, and water-using appliances. This scale can cause premature maintenance and failure. Elimination of hard water also provides substantial energy savings because scale acts as an insulator, wasting electricity or gas used to heat water.

Water For Lawns And Household Plants

If possible, lawn sprinkling faucets should be supplied with hard water primarily because it is not economical to soften so much water.

Household plants are much more sensitive than lawns with respect to the kind of water which is best. First, because they receive no rainfall and, second, there is little or no drainage of the soil. Preferably they should be watered with rainwater or water which is low in mineral content such as distilled or demineralized water. Softened water is not recommended for house plants because a build-up of sodium in the soil may interfere with efficient absorption of water by the plant root system. Additional information may be obtained from your independently operated Culligan dealer.

Culligan Municipal Softener

With the Culligan Municipal softener you will experience the above benefits in addition to the reduction of chlorine taste and odor for a fresh, clean taste and smell.

How Your Water Conditioner Works

Why Water Gets Hard And How It Is Softened

All of the fresh water in the world originally falls as rain, snow, or sleet. Surface water is drawn upward by the sun, forming clouds. Then, nearly pure and soft as it starts to fall, it begins to collect impurities as it passes through smog and dust-laden atmosphere. And as it seeps through soil and rocks it gathers hardness, rust, acid, unpleasant tastes and odors.

Water hardness is caused primarily by limestone dissolved from the earth by rainwater. Because of this, in earlier times people who wanted soft water collected rainwater from roofs in rain barrels and cisterns before it picked up hardness from the earth.

Some localities have corrosive water. A softener cannot correct this problem and so its written warranty disclaims liability for corrosion of plumbing lines, fixtures or appliances. If you suspect corrosion, your Culligan dealer has equipment to control the problem.

Iron is a common water problem. The chemical/physical nature of iron found in natural water supplies is exhibited in four general types:

- Dissolved Iron—Also called ferrous or “clear water” iron. This type of iron can be removed from the water by the same ion exchange principle that removes the hardness elements, calcium and magnesium. Dissolved iron is soluble in water and is detected by taking a sample of the water to be treated in a clear glass. The water in the glass is initially clear, but on standing exposed to the air, it may gradually turn cloudy or colored as it oxidizes.

- Particulate Iron—Also called ferric or colloidal iron. This type of iron is an undissolved particle of iron. A softener will remove larger particles, but they may not be washed out in regeneration effectively and will eventually foul the ion exchange resin. A filtering

treatment will be required to remove this type of iron. - Organic Bound Iron—This type of iron is strongly attached to an organic compound in the water. The ion exchange process alone cannot break this attachment and the softener will not remove this type of iron.

- Bacterial Iron—This type of iron is protected inside a bacteria cell. Like the organic bound iron, it is not removed by a water softener.

When using a softener to remove both hardness and dissolved iron it is important that it regenerates more frequently than ordinarily would be calculated for hardness removal alone. Although many factors and formulas have been used to determine this frequency, it is recommended that the softener be regenerated when it has reached 50–75% of the calculated hardness alone capacity. This will minimize the potential for bed fouling. (Iron removal claims have not been verified by the Water Quality Association and IAPMO R&T.)

If you are operating a water softener on clear water iron, regular resin bed cleaning is needed to keep the bed from coating with iron. Even when operating a softener on water with less than the maximum of dissolved iron, regular cleanings should be performed. Clean every six months or more often if iron appears in your conditioned water supply. Use resin bed cleaning compounds carefully following the

directions on the container.

NOTICE: Do not use where the water is microbiologically unsafe or with water of unknown quality without adequate disinfection before or after the unit.

The Culligan Process

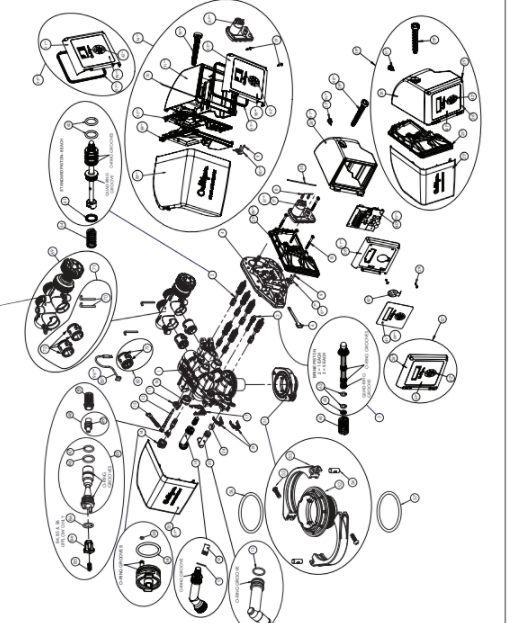

Your Culligan water conditioner consists of three basic components, (A) the Control Valve, (B) the Mineral Tank, and (C) the Brine System.

A. Control Valve

The exclusive Culligan control valve automatically performs a variety of tasks that are necessary for the proper operation of your water conditioner. These tasks, commonly referred to as cycles or operating positions, are Service, Regeneration, and Brine Refill.

- Service: While the control valve is in the service cycle, hard water is directed down through the column of Cullex® resin where hardness minerals are removed from the water. The softened water is then directed into your household plumbing lines. The ability of the Cullex resin to remove hardness minerals needs to be periodically replenished; this is referred to as Regeneration.

- Regeneration: While the control valve is in the regeneration cycle, water is first directed up through the column of Cullex resin to flush

accumulated sediment out of the resin and down the drain. Then, the regenerant brine solution is slowly drawn from the bottom of the salt storage tank of the Brine System and is directed down through the column of Cullex resin, restoring the ability of the resin to remove hardness minerals from your water supply. Once completed, the regeneration cycle is followed by Brine Refill. - Brine Refill: While the control valve is in the brine refill cycle, a predetermined amount of water is directed to the salt storage tank of the Brine System so that additional salt can be dissolved to provide the brine solution that will be needed for the next regeneration cycle.

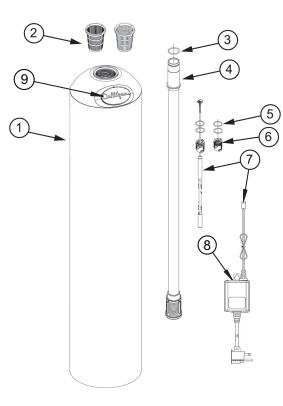

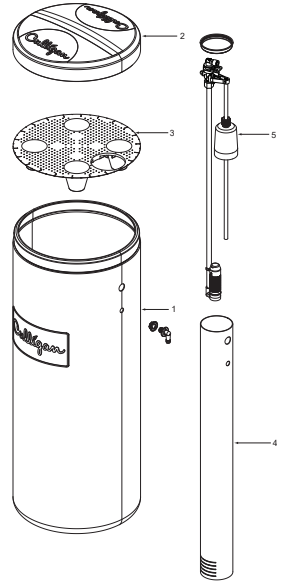

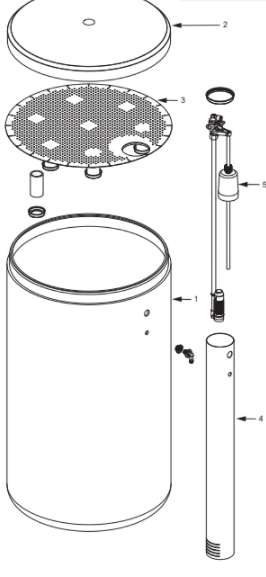

B. The Mineral Tank

The Mineral Tank contains the Cullex resin column, Cullsan® underbedding, and an outlet manifold (the Culligan Municipal also includes carbon media for chlorine taste & odor reduction). The number of gallons of hard water that can be softened by the Cullex resin column before it needs regeneration is called the “capacity” of the resin column, and depends upon the amount of hardness minerals in each gallon of water (expressed as grains per gallon) and upon the amount of regenerant brine solution (expressed as pounds of salt) passed through the resin column during regeneration.

Your Culligan service person, taking into account the hardness of your water and the amount of softened water your household may reasonably expect to use each day, has carefully established how often the softener will regenerate and how much salt will be used for each regeneration. This will ensure that all of your soft water needs will be fulfilled without using an excessive amount of salt.

C. The Brine System

The Brine System consists of a salt storage container and hydraulic Dubl-SafeTM valve. The salt storage container holds the salt that is used to make the regenerant brine solution. The hydraulic Dubl-Safe valve limits the amount of water that is returned to the salt storage tank during the brine refill cycle.

Because a predetermined amount of salt is dissolved with each brine refill cycle, the salt must be periodically replenished in order to maintain efficient operation. Your Culligan service person will be able to tell you about how often salt must be added to the salt storage container.

Modes of Operation

Water Meter Mode

In water meter mode, the controller keeps track of the quantity of water that has flowed through the resin bed. Based on the influent water hardness and the hardness capacity of the resin bed, a service life expectancy in the quantity of softened water is calculated and programmed into the control. When the set point is reached, regeneration is triggered. If the predict mode is not selected the regeneration will start at time of regeneration. In immediate mode the regeneration starts as soon as the regeneration signal is provided. If time clock backup is set and the capacity has not been exhausted but the days since last regen is greater than time clock backup, setting the softener will immediately regenerate.

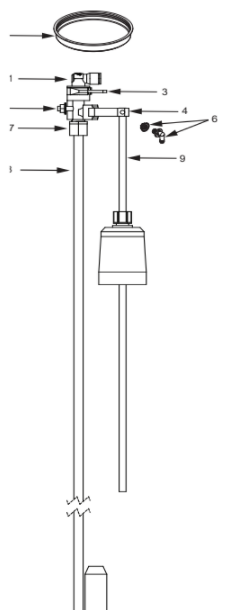

Aqua-Sensor® Mode

The Aqua-Sensor is a conductivity probe that senses when the hardness front passes through the resin bed. It functions independently of the influent water hardness so therefore, is useful in conditions when the influent water hardness varies throughout the year. It provides for the most efficient mode of operation. In addition to sensing when a resin bed is exhausted, it can also be used to determine when the brine solution is rinsed from the resin bed during the Brine Draw/Slow Rinse cycle triggering the control to move to fast rinse. This patented feature provides water savings by optimizing the amount of rinse water required to completely rinse out the resin bed.

Smart Brine Tank Probe

The smart brine tank probe monitors conditions inside the brine tank. It predicts when salt needs to be added to the brine tank, detects the presence of salt-bridging, eductor line plugging and brine tank overfilling.

Wireless Remote Control

The wireless remote control displays the current status of the water softener or filters and allows for remote control. It can be located up to 200 feet away from the softener (depending upon building construction materials). The wireless remote displays information about softener

performance, problems, days of salt remaining and allows remote control for regeneration.

The wireless remote control is designed to communicate at 915 MHz and to work without interference with other 915 MHz devices such as cordless telephones and baby monitors.

Modem

The modem allows for the system to be remotely monitored detecting problems before they occur, to schedule salt delivery when it is needed and to keep the system software up to date with the latest advances.

Culligan Connect TM

The Culligan ConnectTM interface is an intuitive mobile app and is available on both iOS and Android. Users will see their daily and weekly usage patterns graphically represented and instantly updated each time they open the app. In addition, low salt alerts and the ability to put the unit in bypass mode or regeneration from anywhere offer an all new level of control and convenience.

Manual Regeneration

Manual regeneration can be initiated via the softener control valve or wireless remote display. Manual regeneration can be initiated to begin regeneration immediately or that night. To immediately initiate regeneration, press and hold for at least ten (10) seconds. To cancel a delayed regeneration, press and hold for at least five (5) seconds.

Predict Mode

The Predict Mode is used with the flow meter to determine the optimum regeneration point. Before the regeneration starts, the control will compare the remaining capacity value with the average daily water use. If the average daily water usage is less than the reserve capacity, the controller will wait 24 more hours before regeneration. If the reserve capacity is less than the average daily water usage, the control

will initiate regeneration. This works in delay mode only. At any time, if the total capacity value is reached, the control will initiate an immediate regeneration.

Pre-Rinse Mode

The Pre-rinse mode is used to pre-rinse the softener resin bed or filter media. The pre-rinse in flow meter mode will occur after the control has sensed that no water has flowed through the control for a period of X hours (can be set through the programming menu). When the control is in this mode, once the X amount of hours have elapsed the control will cycle to the fast rinse position for the pre-set length of

minutes and then return to the home or service position.

Down Flow Regeneration

Water and regenerate flow downward through the media tank.

Up Flow Regeneration

Water flow is downward and regenerate flow is upward through the media tank. The significance of this is that regeneration will be most effective in those parts of the resin bed which are treated with the freshest regenerate solution. There will tend to be less hardness leakage with up-flow regeneration.

Proportional Brining

The control monitors your softened water usage making only enough brine to regenerate that part of the resin bed that has been exhausted. In this way the amount of salt used relates directly to the amount of softened water used, making it more efficient and cost effective. Proportional brining can only be used with upflow regeneration. The Aqua-Sensor or meter can be used to initiate a regeneration.

Dial-A-Softness®

Dial-A-Softness is a manual adjustment built into the control valve that allows for variable hardness bypass into the softened water. The hard water bypass can be adjusted from 0% to 30%. The Dial-A-Softness also increases the softener capacity in proportion to the percent hard water bypass (less salt used).

Salt Supply, Usage and Service

Salt is the mineral used to “recharge” your water conditioner. A brine solution is automatically made up in the bottom of the salt storage container, the Cullex® resin beads in the mineral tank are flushed with the brine solution as a step in the recharging process.

Your Culligan Water Conditioner has been carefully designed to get the greatest amount of softening capacity from the salt it uses. Here is some pertinent information about salt usage, types and service.

Salt Economizer

This control is set at the time of installation, and determines salt usage according to the water hardness, number of persons in the household, and water usage.

What Kind of Salt is Best

All Culligan Water Conditioners are designed to use any water conditioner salt of good quality, including rock, pellet, solar, or “evaporated” types.

All rock salt, regardless of source, contains insoluble material which collects at the bottom of the salt storage tank and requires periodic clean-out.

If purified salt products are used, the salt storage compartment will require less frequent clean-out,but you must check more frequently for “bridging.”

Regardless of what type of salt is used, we recommend Culligan Brand Salt as suggested by your Culligan Dealer. He or she is the expert and can provide you with the best product for your Culligan Water Conditioner.

Automatic Salt Delivery Service

Ask your Culligan Dealer for details about salt delivery service. You can have your salt supply replenished on a regular basis. Whether you have automatic delivery service or pick up salt from your Culligan Dealer, you will be getting quality salt packaged according to rigid Culligan

specifications. Using Culligan Brand Salt will help assure continued efficiency and trouble-free operation of your water conditioner.

The modem allows for the system to be remotely monitored, detecting problems before they occur, to schedule salt delivery when it is needed and to keep the system software up to date with the latest advances.

NOTICE :Sodium Information: Water softeners using sodium chloride for regeneration add sodium to the water. Persons who are on sodium restricted diets should consider the added sodium as part of their overall sodium intake.

Care and Cleaning of Your Water Conditioner

Following these simple precautions will help assure continued trouble-free service and keep your Culligan Water Conditioner looking like new for years.

- Do not place heavy objects on top of the salt storage tank or timer cover.

- Use only mild soap and warm water when cleaning the exterior of the conditioner. Never use harsh, abrasive cleaning compounds or those which contain acid, such as vinegar, bleach and similar products.

- Important: Protect your water conditioner and the entire drainline from freezing temperatures.

WARNING! DANGER: If your unit should freeze, do not attempt to disassemble it. Call your Culligan Dealer.

- Important: Culligan water softeners are sold for use on potable water only. If at any time the water becomes contaminated, such as during a “boil water” advisory, the operation of the water softener should be discontinued until it is verified that the water is again potable. To do this, turn the blue knob in a clockwise position, then call your Culligan dealer to have your system sanitized before it is placed back into service.

- Should service, adjustment or trouble-shooting information be needed which is not covered in the Use and Care Guide, call your Culligan Dealer.

For parts and service availability please call your local independently operated Culligan dealer. For your nearest Culligan dealer, call (800) 285-5442.

Cleaning Out the Salt Storage Tank

A periodic clean-out of the Salt Storage Tank is necessary to keep your Culligan Water Conditioner at peak operating efficiency. Do it at least every two years when the salt supply is low. Follow these step-by-step procedures:

Tools Needed

• Scoop

• Clean, bucket-size container

• Garden hose

• Household scrub brush or sponge

Procedure

- Remove the salt storage tank cover and the cap from the brine valve chamber.

- Disconnect the brine line from the brine valve by holding the outer ring of the push fitting; push the tubing in slightly before pulling it out.

- Lift the brine valve out of the brine valve chamber and set aside in an upright position.

- If you’d like to save any clean, dry salt remaining in the tank, remove it and place it in a clean container.

- Using the scoop, dig out and discard as much remaining salt, water and debris as possible.

- Remove the brine valve chamber by removing the screws on either side of the salt tank.

- Remove the salt plate at the bottom of the brine tank.

- Lay the salt tank on its side and direct a brisk stream of water from your garden hose to its inside to rinse out all residue.

- Using a household scrub brush and a mild soapy solution, clean the salt plate. This will complete the tank cleaning.

- Insert the brine valve into the chamber and replace brine valve chamber cap. (Re-insert the brine valve into the chamber, re-insert the brine line fully, and replace brine valve chamber cap.)

- Fill the salt storage tank with 4 to 6 inches of water.

- Fill the tank with salt to within a few inches of the top.

- Replace salt storage tank cover.

Sanitizing Procedure

A water softener in daily use on a potable water supply generally requires no special attention other than keeping the salt tank filled. Occasionally, however, a unit may require sanitization under one of the following conditions:

• At start-up time.

• After standing idle for a week or more.

• On private supplies, the appearance of off-tastes and odors, particularly if musty or “rotten egg” (caused by harmless sulfate-reducing bacteria).

NOTE: If the water supply contains iron, regenerate the softener before sanitizing to remove iron from the resin.

CAUTION! Caution! Hazard from toxic fumes! Chlorine bleach and common iron control chemicals may generate toxic fumes when mixed.

If the unit uses any compounds containing sodium hydrosulfite, sodium bisulfite, or any other reducing

agent, disconnect the device feeding the chemical(s) and manually regenerate the unit before sanitizing.

Do not use this procedure if the softener salt contains iron control additives.

- Remove the brine tank cover.

- Pour directly into the brine chamber 1/3 to 1/2 cup of common household bleach (5.25% sodium hypochlorite) for each cubic foot of resin in the tank.

- Manually start recharge. Allow the unit to complete the recharge cycle automatically.

If tastes and odors return frequently, even after sanitization, a continuous chlorination system may be needed. Send a water sample to a qualified laboratory for bacterial analysis.

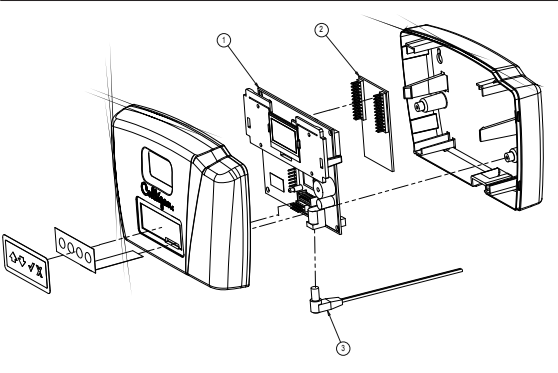

Navigating the Menus and Keypad

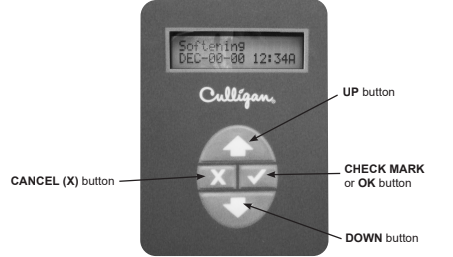

UP ARROW button: scrolls up the menu

DOWN ARROW button: scrolls down the menu

CHECK MARK button: selects the highlighted option, opens a new screen, or accepts a changed setting

CANCEL or X button: returns to the previous screen or cancels a changed setting

NOTE: Hold down up or down button. to quickly scroll through the setting without repeatedly pressing the button.

Set Date and Time

Follow this procedure to update the date or time.

NOTE: The control must be returned to the HOME screen if settings are changed.

N/A

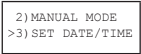

- From the HOME screen, press down

to view the main menu.

1–6

- The screen displays the main menu. Press

to select 3)SET DATE/TIME.

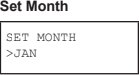

Jan–Dec

- The screen displays the month setting.

Press

or

and then

to change the setting.

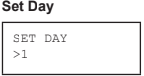

1–31

- The screen displays the day setting. Press or and then to change the setting.

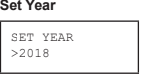

2009– 2030

- The screen displays the year setting. Press or and then to change the setting.

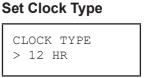

12 HR, 24 HR

- The screen displays the clock type setting. Press or and then to change the setting.

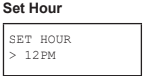

12PM– 11AM, 0–23

- The screen displays the hour setting. Press or and then to change the setting.

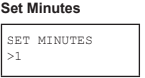

0–59

- The screen displays the minutes setting. Press or and then to change the setting.

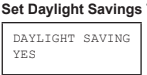

Yes, No

- The screen displays the Daylight Savings Time setting. Press or and then to change the setting.

- The screen displays the main menu. Press X to save the changes and initialize the system.

11. The screen displays the home screen.

Information

The following information can be displayed at the control valve or remote display. These settings are read-only. Press

or

to scroll through the settings. Press

to view the previous setting.

| Screen Display | Range | Setting Description |

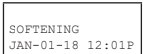

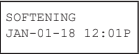

| SOFTENING JAN-01-18 12:01P | N/A | 1.From the HOME screen, press down key to view the main menu. |

| 1)INFORMATION 2)MANUAL MODE | 1–6 | 2.The screen displays the main menu. Press to select 1)INFORMATION. |

| SALT TANK LEVEL OK | OK, Low | 3.If a Salt Brine Tank is installed, this screen displays the salt level. The status is OK unless the SBT probe detects and overfilled brine tank or low salt level. If the screen displays LOW a subsequent screen displays APPROX DAYS OF SALT REMAINING. Press down key to select the next information screen. |

| REMAIN CAPACITY 100% | 0–100 | 4.The screen displays the softening capacity remaining, displayed as a percentage of the total capacity. During manually initiated regeneration, assume 0 percent remaining capacity. Press down key to select the next information screen. |

| REMAIN CAPACITY 740 GAL | 0–no limit | 5.The screen displays the softening capacity remaining, measured in gallons (liters). Press down key to see the next information screen. |

| CURRENT FLOWRATE 0.0 GPM | 0–no limit | 6.The screen displays the current flow rate, measured in gallons (liters) per minute. Press down key to see the next information screen. |

| TODAY’s USAGE 0 GAL | 0–no limit | 7.The screen displays today’s water usage, measured in gallons (liters). Press down key to see the next information screen. |

| AVERAGE DAILY 300 GAL | 0–no limit | 8.The screen displays average water usage for this configuration. Press down key to see the next information screen. |

| NEXT REGEN ON JAN-03 | N/A | 9.The screen displays the date of the next regeneration, based on average daily water usage. Press down key to see the next information screen. |

| DEALER ID | N/A | 10.This is the local dealer’s eight-digit identification number as entered during the First Time Setup. |

| TOTAL WATER USED 1000 GAL | 0–no limit | 11.The screen the total water used for this configuration. Whole numbers are displayed above 100 gallons. Press down key to see the next information screen. |

| EXT FILT CAP REM 20000 GAL | 0–no limit | 12.If an external filter is used, the screen displays the remaining capacity of the filter. When the remaining capacity reaches zero, the system triggers the External Filter Alarm. Press to return to the main menu. |

| 1)INFORMATION 2)MANUAL MODE | 13The screen displays the main menu. Press X to exit to the home screen. | |

| SOFTENING JAN-01-18 12:01P | 14.The screen displays the home screen. |

REGEN Tonite when the control has signaled for a regeneration. Regenerating is displayed while the control is in regeneration .the following condition that will call for regeneration.

- When the Soft-Minder® meter has recorded the passage of a predetermined number of gallons.

- When the Aqua-Sensor® Probe senses the hardness in the Cullex Media.

- At the preset time, when the number of days without a regeneration is equal to the regeneration interval (timeclock backup) setting.

- At the preset time, when Regen Tonite is selected. The screen displays Regen Tonite.

- Immediately, when the Regen Now is selected. The screen displays Regenerating.

- Immediately, if power to the unit has been off for more than three hours and the time of day has been restored.

- At the preset time based on “Day-of-Week” Regeneration setting.

Follow either procedure to initiate a manual regeneration.

Delayed Regeneration

| Screen Display | Range | Setting Description |

| SOFTENING JAN-01-18 12:01P | N/A | 1.From the HOME screen, press and hold for at least three (3)seconds and then release the button. |

| REGEN TONITE JAN-01-18 12:01P | Regen Tonite | 2.The screen displays the regeneration status on the first line of the display. The system will regenerate at a scheduled time. |

| REGEN OFF JAN-01-18 12:01P | Regen Off | 3.To cancel a delayed regeneration, press and hold for at least three (3) seconds and then release the button. The screen displays the new status. |

Immediate Regeneration

| Screen Display | Range | Setting Description |

| SOFTENING JAN-01-18 12:01P | N/A | 1.From the HOME screen, press and hold for at least ten (10) seconds. |

| REGEN NOW JAN-01-18 12:01P | Regen Now | 2.The screen displays the regeneration status on the first line of the display. The softener will initiate an immediate regeneration. |

| REGENERATING JAN-01-18 12:01P | N/A | 3.The first line of the screen displays REGENERATING. |

Standard Manual Regeneration

| Screen Display | Range | Setting Description |

| SOFTENING JAN-01-18 12:01P | N/A | 1.From the HOME screen, press down to view the main menu. |

| 1)INFORMATION 2)MANUAL MODE | 1–6 | 2.The screen displays the main menu. Press down to select 2)MANUAL MODE. |

| MANUAL MODE REGEN NOW | Regen Off Regen Now Regen Tonite Bypass | 3.The screen displays the manual regeneration menu. Press or and then to change the setting. REGEN NOW is the default. REGEN OFF specifies the softener will not regenerate. REGEN TONITE specifies that the softener will regenerate that night at 2:00 a.m. (or at the preset regeneration time). The screen displays two status messages: SOFTENING and REGEN TONITE. BYPASS specifies a preset softener bypass time. Press to select the total time the softener is in the bypass state. |

| MANUAL BYPASS OFF | Off, 30, 60, 90, 120, 180, Manual Bypass | 4.The screen displays the manual bypass duration, in minutes. This specifies the total time the softener is to be in the bypass state. Press or and then to change the setting. |

| SOFTENING JAN-01-18 12:01P | N/A | Press XX to display the home screen. |

Error Codes

The controller display, as well as the Remote Display (if connected), may display the following errors.

| PROBLEM FOUND APR-01-18 10:01A | 1When the controller identifies an error, it is programmed to attempt to correct the error without user input. If the problem persists, the HOME SCREEN displays PROBLEM FOUND. Press to display the first error present. |

| REPLACE FILTER MEDIA | 2.Press to display any additional errors present. |

| –>CLEAR ERRORS | 3.Press and to view action: CLEAR ERRORS, GO TO MENU, or EXIT. If you select CLEAR ERRORS, the controller checks the error status and attempts to clear the error. If the error still exists, the home screen displays PROBLEM FOUND. If the error no longer exists the screen displays SYSTEM OK. |

| –>GO TO MENU | 4.Contact your Culligan dealer. |

When and How to Bypass Your Water Conditioner

Normally, all water except outside lines passes through the water softener. There are times when the water softener should be bypassed, using the Cul-Flo-Valv® Bypass, or a three-way bypass valve. You should bypass:

- If lines to outside faucets do not bypass the water softener, and you do not want to waste softened water on lawn sprinkling or other outside uses.

- If you are going away on vacation and do not want the unit to recharge.

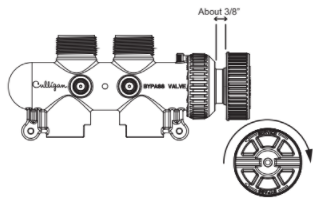

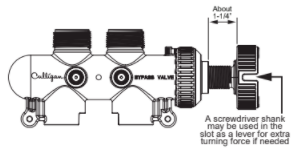

Bypass Valve

In the back of Culligan water softener is a Cul-Flo-Valv® Bypass valve. To bypass the unit, turn the blue knob clockwise. To return to softened water service, turn the blue knob counter-clockwise.

Bypassed

To BYPASS, turn the blue knob clockwise (see directional arrow on end of knob) until the knob stops as shown in Figure 1. DO NOT OVERTIGHTEN!

Softened Water

To return to SERVICE, turn the blue knob counter-clockwise (see directional arrow on end of knob) until the knob stops as shown in Figure 2. DO NOT OVERTIGHTEN!

Things to Check Before You Call for Service

If you unexpectedly experience changes in your water, make these simple checks before calling your Culligan dealer. One of the following conditions may be the reason for your interruption of service.

Important

If any of the following conditions is found, the water softener should be manually regenerated according to instructions on “Standard Manual Regeneration” after you have corrected the problem.

Power Supply

Check your power supply cord. Is it plugged fully into the electric outlet? Be certain that the outlet is not controlled by a wall switch which has been turned off. Plug in the transformer then reset conditioner to the correct time of day.

Blown Fuse

Check the house fuse or circuit breaker panel. Replace a blown-out fuse or reset an open circuit breaker.

Power Failure

Any interruption in your power supply or time change—such as daylight savings—will disrupt your softener’s regeneration schedule by causing the timer to run off-schedule. Reset the timer to the correct time of day.

Bypass Valves

Check to see if they are in the proper position. Cul-Flo-Valv® Bypass, if used, should be in the “Service” position . If hand valves are used, see that inlet and outlet valve are opened and that the bypass valve is closed.

No Water

If you aren’t getting any water flow at all, make sure your water supply is working. Open a tap ahead of the conditioner (outside tap) to see if you have any water pressure. If you have water pressure, check the bypass valve. If it is in the Service position, put it into the bypass and call

your Culligan dealer for service.

Increased Usage

Guests, family additions, new water-using appliances, etc., will result in more water usage and may require additional programming by your local Culligan dealer. Please contact your local Culligan dealer.

Performance Data Sheet

Culligan High Efficiency 9” Water Softener with Soft-Minder® Meter

Culligan knows the more informed you are about your water treatment systems, the more confident you will be about its performance. It’s because of this and more than seventy years of commitment to customer satisfaction that Culligan is providing this Performance Data Sheet to its customers.

NOTICE: Read this Performance Data Sheet and compare the capabilities of this unit with your actual water treatment needs. It is recommended that before purchasing a water treatment unit, you have your water supply tested to determine your actual water treatment needs.

Manufacturer: Culligan International Company 9399 W. Higgins Rd., Suite 1100, Rosemont, IL 60018 USA (847) 430-2800 www.culligan.com

Product: Culligan High Efficiency 9” Water Softener with Soft-Minder® Meter

Testing Conditions & Results:

| Flow Rate: | 9.0 gpm @ 11 psi |

| Pressure: | 30–40 psi (2.1–2.8 kg/cm2) |

| Acidity: | Non-Corrosive |

| Temperature: | 68°F (20°C) |

| Efficiency Rated Dosage† | 4,463 gr/lb |

| Capacity: | 17,854 grains @ 4.0 lb. salt |

| 27,108 grains @ 8.0 lb. salt | |

| 31,736 grains @ 12.0 lb. salt | |

| pH: | 7.6 |

Softener Specifications:

Service Flow Rate: 9.0 gpm

Operating Temp. Range: 33–120°F (0–49°C)

Working Press. Range: 20–125 psi (1.4–8.5 kg/cm2)

Pressure Drop at Max. Flow Rate: 11 psi

Max. Drain Flow Rate: 2.5 gpm

Oper. Press. Range (Canada): 20–90 psi (1.4–6.3 kg/cm2)

| Name of Substance | USEPA Max. Contaminant Level | pH | Flow Rate | Pressure |

| Barium | 2.0 mg/L | 7.5 + 0.5 | 9.0 gpm | 11 (psig) |

| Radium 226/228 | 5 pCi/L | 7.5 + 0.5 | 9.0 gpm | 11 (psig) |

This system is certified for barium and radium 226/228 reduction based on hardness reduction. It is recommended you test your water every 6 months to ensure the system is performing properly and that hardness, and therefore barium and radium 226/228, are being reduced.

The Culligan High Efficiency Series 9” Water Softeners with Soft-Minder® Meter are tested and certified by WQA against NSF/ANSI Standard 372, CSA B483.1, NSF/ANSI Standard 44 for the effective reduction of hardness (calcium and magnesium), barium, and radium 226/228, as verified and substantiated by test data. To maintain product certification and ensure uniform performance, the product is retested on a consistent basis.

The Culligan High Efficiency Series 9” Water Softeners with Soft-Minder® Meter are certified by IAPMO R&T against NSF/ANSI Standard 372, CSA B483.1, NSF/ANSI Standard 44 for the effective reduction of hardness (calcium and magnesium), barium, and radium 226/228, as verified and substantiated by test data. To maintain product certification and ensure uniform performance, the product is retested on a consistent basis.

The Culligan High Efficiency 9” Water Softeners with Soft-Minder® Meter are registered under California Water Treatment Device Registration Number 2044a. The Culligan High Efficiency 9” Water Softeners with Soft-Minder® Meter are registered under Iowa Water Treatment Device Registration Number 20607.

An efficiency rated water softener is a DIR softener which also complies with specific performance specifications intended to minimize the amount of regenerant brine and water used in its operation. Efficiency rated water softeners shall have a rated salt efficiency of not less than 3350 grains of total hardness exchange per pound of salt (based on NaCl equivalency) (477 grams of total hardness exchange per kilogram of salt), and shall not deliver more salt than its listed rating. The efficiency is measured by a laboratory test described in NSF/ANSI 44. The test represents the maximum possible efficiency the system can achieve. Operational efficiency is the actual efficiency achieved after the system has been installed. It is typically less than the efficiency due to individual application factors including water hardness, water usage, and other contaminants that reduce the softener’s capacity.

Refer to the Specifications, Familiarization and Warranty section of this Owner’s Guide (P/N 01021076) for more specific product information. To avoid contamination from improper handling and installation, your system should only be installed and serviced by your Culligan dealer. Performance will vary based on local water conditions. The substances reduced by this system are not necessarily in your water.

Culligan water softeners are designed to work with any salt of good quality, although it is recommended that you ask your local Culligan dealer for his suggestion on the best type and grade of salt to use in this softener.

NOTICE: This softener is not intended to be used for treating water that is microbiologically unsafe or of unknown quality without adequate disinfection before or after the system.

The efficiency rated dosage is only valid at the 4lb. salt dosage and maximum service flow rate for 9” models.

Culligan High Efficiency 9” Water Softener with Aqua-Sensor® Sensing Device

Culligan knows the more informed you are about your water treatment systems, the more confident you will be about its performance. It’s because of this and more than seventy years of commitment to customer satisfaction that Culligan is providing this Performance Data Sheet to its customers.

NOTICE: Read this Performance Data Sheet and compare the capabilities of this unit with your actual water treatment needs. It is recommended that before purchasing a water treatment unit, you have your water supply tested to determine your actual water treatment needs.

Manufacturer: Culligan International Company 9399 W. Higgins Rd., Suite 1100, Rosemont, IL 60018 USA (847) 430-2800 www.culligan.com

Product: Culligan High Efficiency 9” Water Softener with Aqua-Sensor® Sensing Device

Testing Conditions & Results:

| Flow Rate: | 9.0 gpm @ 11 psi |

| Pressure: | 30–40 psi (2.1–2.8 kg/cm2) |

| Acidity: | Non-Corrosive |

| Temperature: | 68°F (20°C) |

| Efficiency Rated Dosage† | 4,463 gr/lb |

| Capacity: | 17,854 grains @ 4.0 lb. salt |

| 27,108 grains @ 8.0 lb. salt | |

| 31,736 grains @ 12.0 lb. salt | |

| pH: | 7.6 |

Softener Specifications:

Service Flow Rate: 9.0 gpm

Operating Temp. Range: 33–120°F (0–49°C)

Working Press. Range: 20–125 psi (1.4–8.5 kg/cm2)

Pressure Drop at Max. Flow Rate: 11 psi

Max. Drain Flow Rate: 2.5 gpm

Oper. Press. Range (Canada): 20–90 psi (1.4–6.3 kg/cm2)

| Name of Substance | USEPA Max. Contaminant Level | pH | Flow Rate | Pressure |

| Barium | 2.0 mg/L | 7.5 + 0.5 | 9.0 gpm | 11 (psig) |

| Radium 226/228 | 5 pCi/L | 7.5 + 0.5 | 9.0 gpm | 11 (psig) |

This system is certified for barium and radium 226/228 reduction based on hardness reduction. It is recommended you test your water every 6 months to ensure the system is performing properly and that hardness, and therefore barium and radium 226/228, are being reduced.

The Culligan High Efficiency 9” Water Softeners with Aqua-Sensor® Sensing Device are tested and certified by WQA against NSF/ANSI Standard 372, CSA B483.1, NSF/ANSI Standard 44 for the effective reduction of hardness (calcium and magnesium), barium, and radium 226/228, as verified and substantiated by test data. To maintain product certification and ensure uniform performance, the product is retested on a consistent basis.

The Culligan High Efficiency 9” Water Softeners with Aqua-Sensor® Sensing Device are certified by IAPMO R&T against NSF/ANSI Standard 372, CSA B483.1, NSF/ANSI Standard 44 for the effective reduction of hardness (calcium and magnesium), barium, and radium 226/228, as verified and substantiated by test data. To maintain product certification and ensure uniform performance, the product is retested on a consistent basis.

The Culligan High Efficiency 9” Water Softeners with Aqua-Sensor® Sensing Device are registered under California Water Treatment Device Registration Number 2044b. The Culligan High Efficiency 9” Water Softeners with Aqua-Sensor® Sensing Device are registered under Iowa Water Treatment Device Registration Number 20607.

An efficiency rated water softener is a DIR softener which also complies with specific performance specifications intended to minimize the amount of regenerant brine and water used in its operation. Efficiency rated water softeners shall have a rated salt efficiency of not less than 3350 grains of total hardness exchange per pound of salt (based on NaCl equivalency) (477 grams of total hardness exchange per kilogram of salt), and shall not deliver more salt than its listed rating. The efficiency is measured by a laboratory test described in NSF/ANSI 44. The test represents the maximum possible efficiency the system can achieve. Operational efficiency is the actual efficiency achieved after the system has been installed. It is typically less than the efficiency due to individual application factors including water hardness, water usage, and other contaminants that reduce the softener’s capacity.

Refer to the Specifications, Familiarization and Warranty section of this Owner’s Guide (P/N 01021076) for more specific product information. To avoid contamination from improper handling and installation, your system should only be installed and serviced by your Culligan dealer. Performance will vary based on local water conditions. The substances reduced by this system are not necessarily in your water.

Culligan water softeners are designed to work with any salt of good quality, although it is recommended that you ask your local Culligan dealer for his suggestion on the best type and grade of salt to use in this softener.

NOTICE: This softener is not intended to be used for treating water that is microbiologically unsafe or of unknown quality without adequate disinfection before or after the system.

The efficiency rated dosage is only valid at the 4lb. salt dosage and maximum service flow rate for 9” models.

Culligan High Efficiency 10” Water Softener with Soft-Minder® Meter

Culligan knows the more informed you are about your water treatment systems, the more confident you will be about its performance. It’s because of this and more than seventy years of commitment to customer satisfaction that Culligan is providing this Performance Data Sheet to its customers.

NOTICE: Read this Performance Data Sheet and compare the capabilities of this unit with your actual water treatment needs. It is recommended that before purchasing a water treatment unit, you have your water supply tested to determine your actual water treatment needs.

Manufacturer: Culligan International Company 9399 W. Higgins Rd., Suite 1100, Rosemont, IL 60018 USA (847) 430-2800 www.culligan.com

Product: Culligan High Efficiency 10” Water Softener with Soft-Minder® Meter

Testing Conditions & Results:

| Flow Rate: | 9.4 gpm @ 12 psi |

| Pressure: | 30–40 psi (2.1–2.8 kg/cm2) |

| Acidity: | Non-Corrosive |

| Temperature: | 68°F (20°C) |

| Efficiency Rated Dosage† | 4,463 gr/lb |

| Capacity: | 26,781 grains @ 6.0 lb. salt |

| 40,662 grains @ 12.0 lb. salt | |

| 47,604 grains @ 18.0 lb. salt | |

| pH: | 7.6 |

Softener Specifications:

Service Flow Rate: 9.4 gpm

Operating Temp. Range: 33–120°F (0–49°C)

Working Press. Range: 20–125 psi (1.4–8.5 kg/cm2)

Pressure Drop at Max. Flow Rate: 12 psi

Max. Drain Flow Rate: 2.5 gpm

Oper. Press. Range (Canada): 20–90 psi (1.4–6.3 kg/cm2)

| Name of Substance | USEPA Max. Contaminant Level | pH | Flow Rate | Pressure |

| Barium | 2.0 mg/L | 7.5 + 0.5 | 9.4 gpm | 12 (psig) |

| Radium 226/228 | 5 pCi/L | 7.5 + 0.5 | 9.4 gpm | 12 (psig) |

This system is certified for barium and radium 226/228 reduction based on hardness reduction. It is recommended you test your water every 6 months to ensure the system is performing properly and that hardness, and therefore barium and radium 226/228, are being reduced.

The Culligan High Efficiency Series 10” Water Softeners with Soft-Minder® Meter are tested and certified by WQA against NSF/ANSI Standard 372, CSA B483.1, NSF/ANSI Standard 44 for the effective reduction of hardness (calcium and magnesium), barium, and radium 226/228, as verified and substantiated by test data. To maintain product certification and ensure uniform performance, the product is retested on a consistent basis.

The Culligan High Efficiency 10” Water Softeners with Soft-Minder® Meter are registered under California Water Treatment Device Registration Number 2043b. The Culligan High Efficiency 10” Water Softeners with Soft-Minder® Meter are registered under Iowa Water Treatment Device Registration Number 20608.

An efficiency rated water softener is a DIR softener which also complies with specific performance specifications intended to minimize the amount of regenerant brine and water used in its operation. Efficiency rated water softeners shall have a rated salt efficiency of not less than 3350 grains of total hardness exchange per pound of salt (based on NaCl equivalency) (477 grams of total hardness exchange per kilogram of salt), and shall not deliver more salt than its listed rating. The efficiency is measured by a laboratory test described in NSF/ANSI 44. The test represents the maximum possible efficiency the system can achieve. Operational efficiency is the actual efficiency achieved after the system has been installed. It is typically less than the efficiency due to individual application factors including water hardness, water usage, and other contaminants that reduce the softener’s capacity.

Refer to the Specifications, Familiarization and Warranty section of this Owner’s Guide (P/N 01021076) for more specific product information. To avoid contamination from improper handling and installation, your system should only be installed and serviced by your Culligan dealer. Performance will vary based on local water conditions. The substances reduced by this system are not necessarily in your water.

Culligan water softeners are designed to work with any salt of good quality, although it is recommended that you ask your local Culligan dealer for his suggestion on the best type and grade of salt to use in this softener.

NOTICE: This softener is not intended to be used for treating water that is microbiologically unsafe or of unknown quality without adequate disinfection before or after the system.

The efficiency rated dosage is only valid at the 6 lb. salt dosage and maximum service flow rate for 10” models.

Culligan High Efficiency 10” Water Softener with Aqua-Sensor® Sensing

Culligan knows the more informed you are about your water treatment systems, the more confident you will be about its performance. It’s because of this and more than seventy years of commitment to customer satisfaction that Culligan is providing this Performance Data Sheet to its customers.

NOTICE: Read this Performance Data Sheet and compare the capabilities of this unit with your actual water treatment needs. It is recommended that before purchasing a water treatment unit, you have your water supply tested to determine your actual water treatment needs.

Manufacturer: Culligan International Company 9399 W. Higgins Rd., Suite 1100, Rosemont, IL 60018 USA (847) 430-2800 www.culligan.com

Product: Culligan High Efficiency 10” Water Softener with Aqua-Sensor® Sensing Device

Testing Conditions & Results:

| Flow Rate: | 9.4 gpm @ 12 psi |

| Pressure: | 30–40 psi (2.1–2.8 kg/cm2) |

| Acidity: | Non-Corrosive |

| Temperature: | 68°F (20°C) |

| Efficiency Rated Dosage† | 4,463 gr/lb |

| Capacity: | 26,781 grains @ 6.0 lb. salt |

| 40,662 grains @ 12.0 lb. salt | |

| 47,604 grains @ 18.0 lb. salt | |

| pH: | 7.6 |

Softener Specifications:

Service Flow Rate: 9.4 gpm

Operating Temp. Range: 33–120°F (0–49°C)

Working Press. Range: 20–125 psi (1.4–8.5 kg/cm2)

Pressure Drop at Max. Flow Rate: 12 psi

Max. Drain Flow Rate: 2.0 gpm

Oper. Press. Range (Canada): 20–90 psi (1.4–6.3 kg/cm2)

| Name of Substance | USEPA Max. Contaminant Level | pH | Flow Rate | Pressure |

| Barium | 2.0 mg/L | 7.5 + 0.5 | 9.4 gpm | 12 (psig) |

| Radium 226/228 | 5 pCi/L | 7.5 + 0.5 | 9.4 gpm | 12 (psig) |

This system is certified for barium and radium 226/228 reduction based on hardness reduction. It is recommended you test your water every 6 months to ensure the system is performing properly and that hardness, and therefore barium and radium 226/228, are being reduced.

The Culligan High Efficiency 10” Water Softeners with Aqua-Sensor® Sensing Device are tested and certified by WQA against NSF/ANSI Standard 372, CSA B483.1, NSF/ANSI Standard 44 for the effective reduction of hardness (calcium and magnesium), barium, and radium 226/228, as verified and substantiated by test data. To maintain product certification and ensure uniform performance, the product is retested on a consistent basis.

The Culligan High Efficiency 10” Water Softeners with Aqua-Sensor® Sensing Device are certified by IAPMO R&T against NSF/ANSI Standard 372, CSA B483.1, NSF/ANSI Standard 44 for the effective reduction of hardness (calcium and magnesium), barium, and radium 226/228, as verified and substantiated by test data. To maintain product certification and ensure uniform performance, the product is retested on a consistent basis.

The Culligan High Efficiency 10” Water Softeners with Aqua-Sensor® Sensing Device are registered under California Water Treatment Device Registration Number 2043a. The Culligan High Efficiency 10” Water Softeners with Aqua-Sensor® Sensing Device are registered under Iowa Water Treatment Device Registration Number 20608.

An efficiency rated water softener is a DIR softener which also complies with specific performance specifications intended to minimize the amount of regenerant brine and water used in its operation. Efficiency rated water softeners shall have a rated salt efficiency of not less than 3350 grains of total hardness exchange per pound of salt (based on NaCl equivalency) (477 grams of total hardness exchange per kilogram of salt), and shall not deliver more salt than its listed rating. The efficiency is measured by a laboratory test described in NSF/ANSI 44. The test represents the maximum possible efficiency the system can achieve. Operational efficiency is the actual efficiency achieved after the system has been installed. It is typically less than the efficiency due to individual application factors including water hardness, water usage, and other contaminants that reduce the softener’s capacity.

Refer to the Specifications, Familiarization and Warranty section of this Owner’s Guide (P/N 01021076) for more specific product information. To avoid contamination from improper handling and installation, your system should only be installed and serviced by your Culligan dealer. Performance will vary based on local water conditions. The substances reduced by this system are not necessarily in your water.

Culligan water softeners are designed to work with any salt of good quality, although it is recommended that you ask your local Culligan dealer for his suggestion on the best type and grade of salt to use in this softener.

NOTICE: This softener is not intended to be used for treating water that is microbiologically unsafe or of unknown quality without adequate disinfection before or after the system.

The efficiency rated dosage is only valid at the 6lb. salt dosage and maximum service flow rate for 10” models.

Culligan knows the more informed you are about your water treatment systems, the more confident you will be about its performance. It’s because of this and more than seventy years of commitment to customer satisfaction that Culligan is providing this Performance Data Sheet to its customers.

Manufacturer: Culligan International Company 9399 W. Higgins Rd., Suite 1100, Rosemont, IL 60018 USA (847) 430-2800 www.culligan.com

Product: Culligan High Efficiency 12” Water Softener with Soft-Minder® Meter

Testing Conditions & Results:

Flow Rate: 10.0 gpm @ 10 psi

Pressure: 30–40 psi (2.1–2.8 kg/cm2)

Acidity: Non-Corrosive

Temperature: 68°F (20°C)

Efficiency Rated Dosage† : 4,479 gr/lb

Capacity: 31,352 grains @ 7.0 lb. salt

48,458 grains @ 16.0 lb. salt

59,267 grains @ 24.0 lb. salt

pH: 7.6

Softener Specifications:

Service Flow Rate: 10.0 gpm

Operating Temp. Range: 33–120°F (0–49°C)

Working Press. Range: 20–125 psi (1.4–8.5 kg/cm2)

Pressure Drop at Max. Flow Rate: 10 psi (71 kPa)

Max. Drain Flow Rate: 3.0 gpm

Oper. Press. Range (Canada): 20–90 psi (1.4–6.3 kg/cm2)

| Name of Substance | USEPA Max. Contaminant Level | pH | Flow Rate | Pressure |

| Barium | 2.0 mg/L | 7.5 + 0.5 | 10.0 gpm | 10 (psig) |

| Radium 226/228 | 5 pCi/L | 7.5 + 0.5 | 10.0 gpm | 10 (psig) |

This system is certified for barium and radium 226/228 reduction based on hardness reduction. It is recommended you test your water every 6 months to ensure the system is performing properly and that hardness, and therefore barium and radium 226/228, are being reduced.

The Culligan High Efficiency Series 12” Water Softeners with Soft-Minder® Meter are tested and certified by WQA against NSF/ANSI Standard 372, CSA B483.1, NSF/ANSI Standard 44 for the effective reduction of hardness (calcium and magnesium), barium, and radium 226/228, as verified and substantiated by test data. To maintain product certification and ensure uniform performance, the product is retested on a consistent basis.

The Culligan High Efficiency Series 12” Water Softeners with Soft-Minder® Meter are certified by IAPMO R&T against NSF/ANSI Standard 372, CSA B483.1, NSF/ANSI Standard 44 for the effective reduction of hardness (calcium and magnesium), barium, and radium 226/228, as verified and substantiated by test data. To maintain product certification and ensure uniform performance, the product is retested on a consistent basis.

The Culligan High Efficiency 12” Water Softeners with Soft-Minder® Meter are registered under California Water Treatment Device Registration Number 2046b. The Culligan High Efficiency 12” Water Softeners with Soft-Minder® Meter are registered under Iowa Water Treatment Device Registration Number 20609.

An efficiency rated water softener is a DIR softener which also complies with specific performance specifications intended to minimize the amount of regenerant brine and water used in its operation. Efficiency rated water softeners shall have a rated salt efficiency of not less than 3350 grains of total hardness exchange per pound of salt (based on NaCl equivalency) (477 grams of total hardness exchange per kilogram of salt), and shall not deliver more salt than its listed rating. The efficiency is measured by a laboratory test described in NSF/ANSI 44. The test represents the maximum possible efficiency the system can achieve. Operational efficiency is the actual efficiency achieved after the system has been installed. It is typically less than the efficiency due to individual application factors including water hardness, water usage, and other contaminants that reduce the softener’s capacity.

Refer to the Specifications, Familiarization and Warranty section of this Owner’s Guide (P/N 01021076) for more specific product information. To avoid contamination from improper handling and installation, your system should only be installed and serviced by your Culligan dealer. Performance will vary based on local water conditions. The substances reduced by this system are not necessarily in your water.

Culligan water softeners are designed to work with any salt of good quality, although it is recommended that you ask your local Culligan dealer for his suggestion on the best type and grade of salt to use in this softener.

NOTICE: This softener is not intended to be used for treating water that is microbiologically unsafe or of unknown quality without adequate disinfection before or after the system.

The efficiency rated dosage is only valid at the 8 lb. salt dosage and maximum service flow rate for 12” models.

Culligan High Efficiency 12” Water Softener with Aqua-Sensor® Sensing Device

Culligan knows the more informed you are about your water treatment systems, the more confident you will be about its performance. It’s because of this and more than seventy years of commitment to customer satisfaction that Culligan is providing this Performance Data Sheet to its customers.

NOTICE: Read this Performance Data Sheet and compare the capabilities of this unit with your actual water treatment needs. It is recommended that before purchasing a water treatment unit, you have your water supply tested to determine your actual water treatment needs.

Manufacturer: Culligan International Company 9399 W. Higgins Rd., Suite 1100, Rosemont, IL 60018 USA (847) 430-2800 www.culligan.com

Product: Culligan High Efficiency 12” Water Softener with Aqua-Sensor® Sensing Device

Testing Conditions & Results:

| Flow Rate: | 10.0 gpm @ 10 psi |

| Pressure: | 30–40 psi (2.1–2.8 kg/cm2) |

| Acidity: | Non-Corrosive |

| Temperature: | 68°F (20°C) |

| Efficiency Rated Dosage† | 4,479 gr/lb |

| Capacity: | 31,352 grains @ 7.0 lb. salt |

| 48,458 grains @ 16.0 lb. salt | |

| 59,267 grains @ 24.0 lb. salt | |

| pH: | 7.6 |

Softener Specifications:

Service Flow Rate: 10.0 gpm

Operating Temp. Range: 33–120°F (0–49°C)

Working Press. Range: 20–125 psi (1.4–8.5 kg/cm2)

Pressure Drop at Max. Flow Rate: 10 psi (71 kPa)

Max. Drain Flow Rate: 3.0 gpm

Oper. Press. Range (Canada): 20–90 psi (1.4–6.3 kg/cm2)

| Name of Substance | USEPA Max. Contaminant Level | pH | Flow Rate | Pressure |

| Barium | 2.0 mg/L | 7.5 + 0.5 | 10.0 gpm | 10 (psig) |

| Radium 226/228 | 5 pCi/L | 7.5 + 0.5 | 10.0 gpm | 10 (psig) |