20-GALLON PORTABLE AIR COMPRESSOR

Questions, problems, missing parts?

Before returning to the store, call Husky Customer Service

8 a.m. – 6 p.m., EST, Monday – Friday

1-888-43-HUSKY

HUSKYTOOLS.COM

THANK YOU

We appreciate the trust and confidence you have placed in Husky through the purchase of this air compressor.

We strive to continually create quality products designed to enhance your home. Visit us online to see our full line of products available for your home improvement needs. Thank you for choosing Husky!

Safety Information

This manual contains information that is important for you to know and understand. This information relates to protecting your safety and preventing equipment

problems. To help you recognize this information, we use the symbols below. Please read the manual and pay attention to these symbols.

DANGER: Indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury.

WARNING: Indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.

CAUTION: Indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury.

NOTICE: Indicates a practice not related to personal injury which, if not avoided, may result in property damage.

WORK AREA SAFETY

- .Keep your work area clean and well lit. Ensure floors are not slippery from wax or dust.

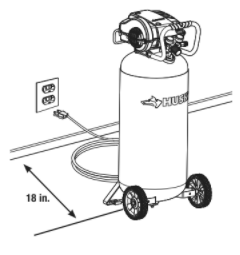

- .Operate the air compressor in an open area at least 18 in. (0.5 m) away from any wall or object that could restrict the flow of fresh air to ventilation openings.

WARNING: Do not operate power tools in explosive atmospheres, such as in the presence of flammable liquids, gases, or dust. Power tools create sparks which

may ignite the dust or fumes. Keep bystanders, children, and visitors away while operating tools. Distractions can cause you to lose control.

WARNING: This compressor is not equipped for, and should not be used to supply breathing air. Additional equipment would be necessary to properly filter and

purify the air to meet minimal specifications for Grade D breathing as described in Compressed Gas Association Commodity, Specification G 7.1 – 1966, OSHA 29 CF91910.134. Compressed Gas Association, 4221 Walney Road, Fifth Floor, Chantilly, VA 20151-2923, (703) 788-2700, www.cganet.com. Any such additional equipment has not been examined and no implication of proper use for breathing air is intended or implied.

CAUTION: Always disconnect the air supply and power supply before making adjustments, servicing a tool, or when a tool is not in use.

PERSONAL SAFETY

- Keep proper footing and balance at all times. Proper footing and balance enables better control of the tool in unexpected situations

- Do not use on a ladder or unstable support.

WARNING: Operating any power tool can result in foreign objects being thrown into your eyes, which can result in severe eye damage. Before beginning operation, always wear safety goggles, safety glasses with side shields, or a full face shield when needed. Always use eye protection marked to comply with ANSI Z87.1.

WARNING: This product contains chemicals known to the State of California to cause cancer and birth defects or other reproductive harm. Wash hands after handling.

WARNING: Use safety equipment. Always wear eye protection with side shields when operating power tools.

A dusk mask, non-skid safety shoes, hard hat, or hearing protection must be used for appropriate conditions.

WARNING: Stay alert when operating a power tool. Do not use the tool while tired or under the influence of drugs, alcohol, or medication.

WARNING: Do not wear loose clothing or jewelry.

Contain long hair. Keep your hair, clothing, and gloves away from moving parts. Loose clothes, jewelry, or long hair can be caught in moving parts.

WARNING: Never touch any exposed metal parts on compressor during or immediately after operation. The compressor will remain hot for several minutes after

operation. Do not reach around protective shrouds or attempt maintenance until the unit has been allowed to cool.

CAUTION: The compressor is too heavy to be lifted by one person. Obtain assistance from others before lifting.

MOVING THE AIR COMPRESSOR

- Grasp the handle of the compressor and tilt the compressor back to rest on the wheels.

- When the location is reached, slowly lower the compressor to the ground. Always store the compressor in a vertical position resting on the rubber bumpers and wheels.

- When transporting the compressor in a vehicle, trailer, etc., make sure the tank is drained and the unit is secured with straps to prevent tipping. Use care when driving to prevent tipping the unit over in the vehicle. Damage can occur to the compressor or surrounding items if the compressor is tipped.

Always use two people when lifting and lift from the recommended lifting points. Do not lift by the wheels or shroud.

WARNING: Risk of unsafe operation. Ensure proper footing and use caution when rolling the compressor so that the unit does not tip or cause loss of balance.

CAUTION: The wheels and handle do not provide adequate clearance, stability, or support for pulling the unit up and down stairs or steps. The unit must be lifted or pushed up a ramp.

AIR COMPRESSOR AND PNEUMATIC TOOL SAFETY

Keep compressors as far from the spraying area as possible: at least 15 ft. (0.4 m) from the spraying area and all explosive vapors.

- If connected to a circuit protected by fuses, use time- delay fuses with this product.

- Ensure the hose is free of obstructions or snags. Entangled or snarled hoses can cause loss of balance or footing, and may become damaged.

- Use the air compressor only for its intended use. Do not alter or modify the unit from the original design or function. Never weld or drill holes in the air tank.

- Never leave a tool unattended with the air hose attached.

- Do not operate this tool if it does not contain a legible warning label.

- Do not continue to use a tool or hose that leaks air or does not function properly.

- Do not attempt to pull or carry the air compressor by the hose.

- Your tool may require more air consumption than this air compressor is capable of providing.

- Never direct a jet of compressed air toward people or animals.

- Protect your lungs. Wear a face or dust mask if the operation is dusty.

- Do not use this air compressor to spray chemicals. Your lungs can be damaged by inhaling toxic fumes. A respirator may be necessary in dusty environments or when spraying paint.

- This compressor is equipped with a thermal overload protector which will shut off the motor if it becomes overheated.

WARNING: Do not attempt to modify this tool or create accessories not recommended for use with this tool. Any such alteration or modification is misuse and could result in a hazardous condition leading to possible serious personal injury.

CAUTION: Do not use the compressor in an environment that is dusty or otherwise contaminated. Using the air compressor in this type of environment may cause damage to the unit.

CAUTION: Risk of bursting. Do not adjust the regulator to result in output pressure greater than the marked maximum pressure of the attachment. Do not use at

pressure greater than the rated maximum pressure of this compressor.

CAUTION: To reduce the risk of electric shock, do not expose the compressor to rain. Store indoors.

ELECTRICAL SAFETY (EXTENSION CORDS)

- Use only 3-wire extension cords that have 3-prong grounding plugs and 3-pole receptacles that accept the product’s plug. When using a power tool at a considerable distance from the power source, use an extension cord heavy enough to carry the current that the product will draw. An undersized extension cord will cause a drop in line voltage, resulting in a loss of power and causing the motor to overheat.

- □ Use the chart provided below to determine the minimum wire size required in an extension cord. Only round jacketed cords listed by Underwriter’s Laboratories (UL) should be used.

- □ Only use 50 feet or less, round jacketed cords listed by Underwriter’s Laboratories (UL).

- □ When operating a power tool outside, use an outdoor extension cord marked “W-A” or “W”.

- These cords are rated for outdoor use and reduce the risk of electric shock.

| Ampere rating (on air compressor data plate) | |

| 14-16 | |

| Cord Length | Wire Size (AWG) |

| 25 ft. | 16 |

| 50 ft. | 12 |

| Used on 12 gauge – 20 amp circuit. NOTE: AWG=American Wire Gauge |

WARNING: When using an extension cord, keep it clear of the working area. Position the cord so that it will not get caught on lumber, tools, or other obstructions while you are working with a power tool. Failure to do so can result n serious personal injury.

WARNING: Check extension cords before each use. If damaged, replace immediately. Never use the air compressor with a damaged cord since touching the

damaged area could cause electrical shock resulting in serious personal injury.

WARNING: Improperly connecting the equipment-grounding conductor can result in a risk of electrical shock.

CAUTION: Avoid body contact with grounded surfaces such as pipes, radiators, ranges, and refrigerators. There is an increased risk of electric shock if your body is grounded.

CAUTION: Do not expose power tools to rain or wet conditions. Water entering a power tool will increase the risk of electric shock.

CAUTION: Replace damaged cords/wiring immediately. Damaged cords/wiring increase the risk of electric shock.

NOTICE: Use longer air hoses instead of long extension cords. Your air compressor will run better and last longer.

ELECTRICAL SAFETY (ELECTRICAL CONNECTION)

- .This air compressor is powered by a precision built electric motor. It should be connected to a power supply that is 120 volts, 60 Hz, AC only (normal household current).

- Do not operate this tool on direct current (DC). A substantial voltage drop will cause a loss of power and the motor will overheat. If the air compressor does not operate when plugged into an outlet, double check the power supply.

ELECTRICAL SAFETY (SPEED AND WIRING)

□ The no-load pump speed of this product is approximately 3,850 rpm. This speed is not constant and

decreases under a load or with lower voltage.

□ For voltage, the wiring in a shop is as important as the motor’s horsepower rating. A line intended only for

lights cannot properly carry a power tool motor. Wire that is heavy enough for a short distance will be too

light for a greater distance. A line that can support one power tool may not be able to support two or three

products.

ELECTRICAL SAFETY (GROUNDING INSTRUCTIONS)

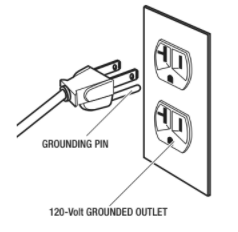

- .This product must be grounded. In the event of an electrical short circuit, grounding reduces the risk of electric shock by providing an escape wire for electric current. This product is equipped with a cord having a grounding wire with an appropriate grounding plug. The plug must be plugged into an outlet that is properly installed and grounded in accordance with all local codes and ordinances.

- WARNING: Improper installation of the grounding plug may result in a risk of electric shock. When repair or replacement of the cord or plug is required, do not connect the grounding wire to either flat blade terminal. The wire with insulation having an outer surface that is green with or without yellow stripes is the grounding wire.

- Check with a qualified electrician or service personnel if these instructions are not completely understood or if in doubt as to whether the tool is

- properly grounded.

- □ Do not modify the plug provided; if it will not fit the outlet, have the proper outlet installed by a qualified electrician.

- □ This product is for use on a nominal 120-Volt circuit and has a grounding plug similar to the plug shown. Only connect the product to an outlet having the same configuration as the plug. Do not use an adapter with this product.

Warranty

LIMITED WARRANTY

WHAT IS COVERED

The manufacturer warrants to the original retail purchaser that this product is free from defect in material and workmanship and agrees to repair or replace, at the manufacturer’s discretion, any defective product free of charge within these time periods from the date of purchase.

This warranty is valid for two (2) years if the product is used for personal, family, or household use, and ninety (90) days if used for any other purpose, such as commercial or rental use.

This warranty extends to the original retail purchaser only and commences on the date of the original retail purchase.

Any part of the product manufactured or supplied by the manufacturer and found in the reasonable judgment of the manufacturer to be defective in material or workmanship will be repaired or replaced by an authorized service dealer without charge for parts and labor.

The product, including any defective part, must be returned to an authorized service dealer within the warranty period. The expense of delivering the manufacturer’s product to the dealer for warranty work and the expense of returning it back to the owner after repair or replacement will be paid by the owner. The manufacturer’s responsibility in respect to claims is limited to making the required repairs or replacements and no claim of breach of warranty shall be cause for cancellation or rescission of the contract of sale of any of the manufacturer’s product.

Proof of purchase will be required by the dealer to substantiate any warranty claim. All warranty work must be performed by an authorized service dealer.

WHAT IS NOT COVERED

This warranty does not cover any of the manufacturer’s product that has been subject to misuse, neglect, negligence, accident, or that has been operated in any way contrary to the operating instructions as specified in this manual. This warranty does not apply to any damage to the manufacturer’s product that is the result of improper maintenance or to any manufacturer’s product that has been altered or modified. The warranty does not extend to repairs made necessary by normal wear or by the use of parts or accessories which are either incompatible with the manufacturer’s product or adversely affect its operation, performance, or durability.

The manufacturer reserves the right to change or improve the design of any product without assuming any obligation to modify any product previously manufactured. All implied warranties are limited in duration to the stated warranty period. Accordingly, any such implied warranties including merchantability, fitness for a particular purpose, or otherwise, are disclaimed in their entirety after the expiration of the appropriate two-year or ninety day warranty period. The manufacturer’s obligation under this warranty is strictly and exclusively limited to the repair or replacement of defective parts and the manufacturer does not assume or authorize anyone to assume for it any other obligation. Some states do not allow limitations on how long an implied warranty lasts, so the above limitation may not apply to you. The manufacturer assumes no responsibility for incidental, consequential, or other damages including, but not limited to, expense of returning the manufacturer’s product to an authorized service dealer and expense of delivering it back to the owner, mechanic’s travel time, telephone or telegram charges, rental of a like product during the time warranty service is being performed, travel, loss or damage to personal property, loss

of revenue, loss of use of the product, loss of time, or inconvenience. Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation or exclusion may not apply to you.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

Contact the Customer Service Team at 1-888-43-HUSKY or visit www.huskytools.com.

Pre-Operation

SPECIFICATIONS

| Running horsepower | 1.3 HP |

| Air tank capacity | 20 gal |

| Air pressure | 175 PSI max. |

| Air delivery | 5.2 SCFM at 40 PSI |

| 4.0 SCFM at 90 PSI | |

| Tank Fill-up Time | 7 minutes |

| Lubrication | Oil free |

| Input | 120V, 60 Hz, Single phase AC only, 15 Amps. |

| Minimum branch circuit requirement | 15 A |

| Fuse type | Time delay |

| Net weight | 73 lbs. |

DUTY CYCLE

This air compressor pump is capable of running continuously. However, to prolong the life of your air compressor, it is recommended that a 50% average duty cycle be maintained; that is, the air compressor pump should not run more than 30 minutes in any given hour.

PACKAGE CONTENTS

| Part | Description | Quantity |

| A | Air Compressor Unit (fully assembled) | 1 |

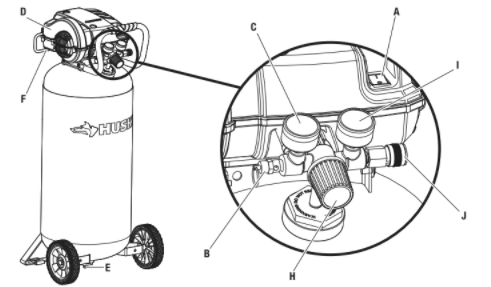

SYSTEM COMPONENTS

| Part | Description |

| A | ON ( I )/OFF ( 0 ) Switch: Turn this switch in the “ON ( I )” position to provide automatic power to the pressure switch and “OFF ( O )” to remove power at the end of each use. |

| B | Safety Valve: If the pressure switch does not shut off the air compressor at its “cut-out” pressure setting, the safety valve will protect against high pressure by “popping out” at its factory set pressure (slightly higher than the pressure switch “cut-out” setting). |

| C | Tank Pressure Gauge: The tank pressure gauge indicates the reserve air pressure in the tank. |

| D | Air Compressor Pump: Compresses air into the air tank. Working air is not available until the compressor has raised the air tank pressure above that required at the air outlet. |

| E | Drain Valve: The drain valve is located at the base of the air tank and is used to drain condensation at the end of each use. |

| F | Check Valve: When the air compressor is operating, the check valve is “open”, allowing compressed air to enter the air tank. When the air compressor reaches “cut-out” pressure, the check valve “closes”, allowing air pressure to remain inside the air tank. |

| G | Thermal Overload Reset: (not shown) This motor has a manual thermal overload protector. If the motor overheats for any reason, the overload protector will shut off the motor. The motor must be allowed to cool down before restarting. To restart: 1. Place the ON/OFF switch in the “OFF” ( O ) position and unplug. 2. Allow the motor to cool. 3. Plug the air compressor into an approved outlet. 4. Place the ON/OFF switch in the “ON” ( I ) position to restart the motor. |

| H | Regulator: Valve used to ensure that the tank pressure never reaches unsafe levels. It also allows the user to adjust the pressure coming out of the tank to match what is needed for the task. |

| I | Pressure Regulator Gauge: The gauge that indicates the amount of pressure that the regulator is providing to the tool. |

| J | Quick Connect: Fitting that is designed to accept a hose that allows pressure to be released for tool usage. |

PLACEMENT OF THE AIR COMPRESSOR

WARNING: If any parts are damaged or missing do not operate this product until the parts are replaced.

Failure to heed this warning could result in serious personal injury.

CAUTION: Do not use in an environment that is dusty or otherwise contaminated. Using the air compressor in this type of environment may cause damage to

the unit.

NOTICE: Long lengths of electrical wiring could cause power loss to the motor.

- Place the air compressor in a clean, dry, and well ventilated area.

- □ The air compressor must be positioned at least 18 in. (0.5 m) away from the wall or other obstructions that will interfere with the flow of air.

- □ Locate the air compressor as close to the main power supply as possible to avoid using long lengths of electrical wiring.

- □ The air filter must be kept clear of obstructions which could reduce the air flow to the air compressor.