Fire or Explosion Hazard: Can cause property damage, severe injury, or death. To prevent possible hazardous burner operation, verify safety requirements each time a control is installed on a burner.

Electrical Shock Hazard: Can cause serious injury or death. Disconnect the power supply before beginning installation. More than one power supply disconnect may be required.

APPLICATION

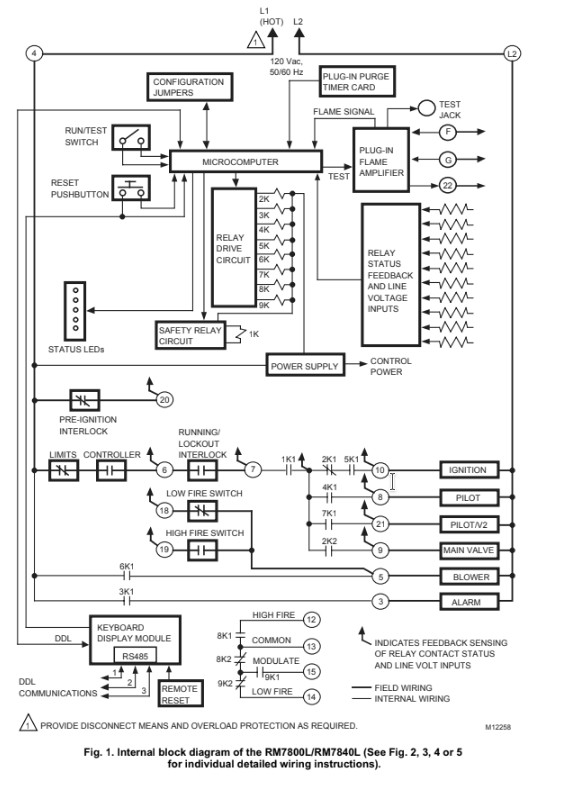

The Honeywell RM7800/RM7840 Relay Modules are microprocessor-based integrated burner controls for automatically fired gas, oil, or combination fuel single burner applications. The RM7800/RM7840 Relay Modules are used for UL/CSA On/Off, UL/CSA Modulating, and FM/IRI Modulating burner applications. The RM7800/RM7840 system consists of a Relay Module. Keyboard Display Modules (standard with RM7800), Dust Cover (standard with RM7840), Subbase, Amplifier, and Purge Card. Options include Personal Computer Interface, DATA CONTROLBUS MODULE™, Remote Display Mounting, First-Out Expanded Annunciator and Combustion System Manager™ Software.

Functions provided by the RM7800/RM7840 include automatic burner sequencing, flame supervision, system status indication, system or self-diagnostics and troubleshooting. The RM7800/RM7840 is a solid state replacement for the electromechanical R4140 Automatic Programming Control.

This document provides installation and static checkout instructions. Other applicable publications are:

- 65-0084:Q7800A,B 22-Terminal Wiring Subbase Product Data.

- 65-0089:ST7800A Plug-In Purge Timer Installation Instructions.

- 65-0090:S7800A Keyboard Display Module Product Data.

- 65-0091:S7810A Data ControlBus Module™ Product Data.

- 65-0095:S7820 Remote Reset Module Product Data.

- 65-0097:221729C Dust Cover Packing Sheet.

- 65-0101:S7830 Expanded Annunciator Product Data.

- 65-0109:R7824, R7847, R7848, R7849, R7851, R7861,R7886 Flame Amplifiers for the 7800 SERIES Product Data.

- 65-0131:221818A Extension Cable Assembly Product Data.

- 65-0228:7800 SERIES Multi-Drop Switch Module Product Data.

- 65-0229:7800 SERIES RELAY MODULES Checkout and Troubleshooting Product Data.

- 65-0249:S7810M ModBus™ Module Product Data.

SPECIFICATIONS

Electrical Ratings, see Table 3:

- Voltage and Frequency: 120 Vac (+10/-15%), 50 or 60 Hz (+10%).

- Power Dissipation: RM7800/RM7840: 10W maximum.

- Maximum Total Connected Load: 2000 VA.

- Fusing: 15A maximum, Type SC or equivalent Fast Blow.

Environmental Ratings:

Ambient Temperature:

- Operating: -40°F to +140°F (-40°C to +60°C).

- Storage: -40°F to +150°F (-40°C to +66°C).

Humidity: 85% relative humidity continuous, noncondensing.

Vibration: 0.5G environment.

Approvals:

Underwriters Laboratories Inc. Listed: File No. MP268, Guide No. MCCZ.

Canadian Standards Association Certified: LR9S329-3.

Factory Mutual Approved: Report No. J.1.1V9A0.AF.

IRI Acceptable.

Federal Communications Commission, Part 15, Class B—Emissions.

INSTALLATION

When Installing this Product…

- Read these instructions carefully. Failure to follow them could damage the product or cause a hazardous condition.

- Check the ratings given in the instructions and marked on the product to make sure the product is suitable for the application.

- Installer must be a trained, experienced, flame safeguard service technician.

- After installation is complete, check out the product operation as provided in these instructions.

Fire or Explosion Hazard: Can cause property damage, severe injury, or death. To prevent possible hazardous burner operation, verify safety requirements each time a control is installed on a burner.

Electrical Shock Hazard: Can cause serious injury or death. Disconnect the power supply before beginning installation. More than one power supply disconnect may be required.

IMPORTANT

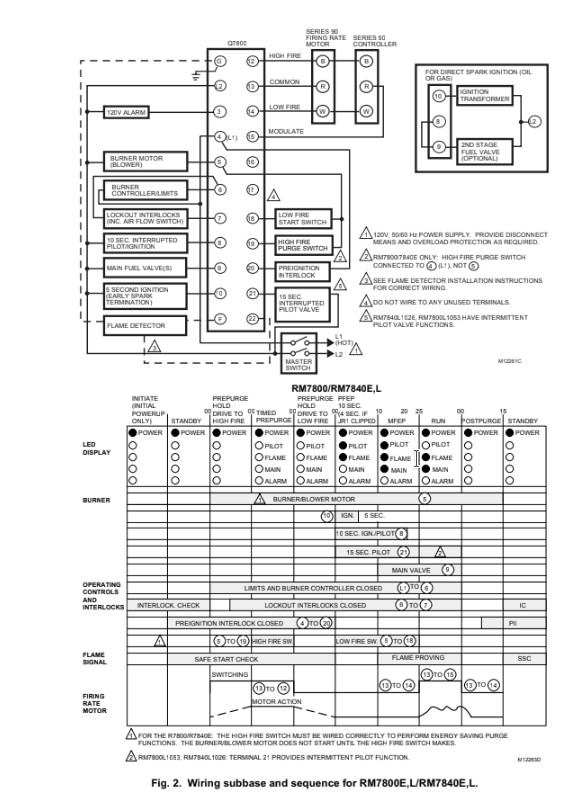

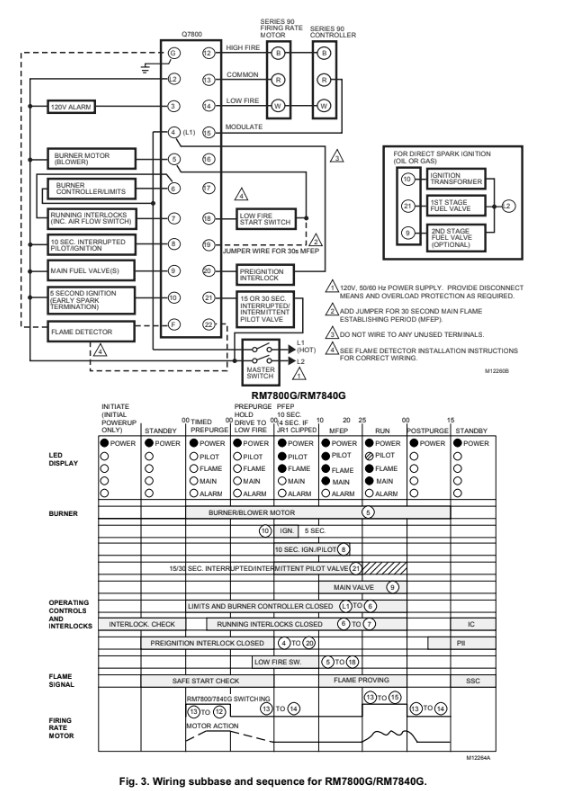

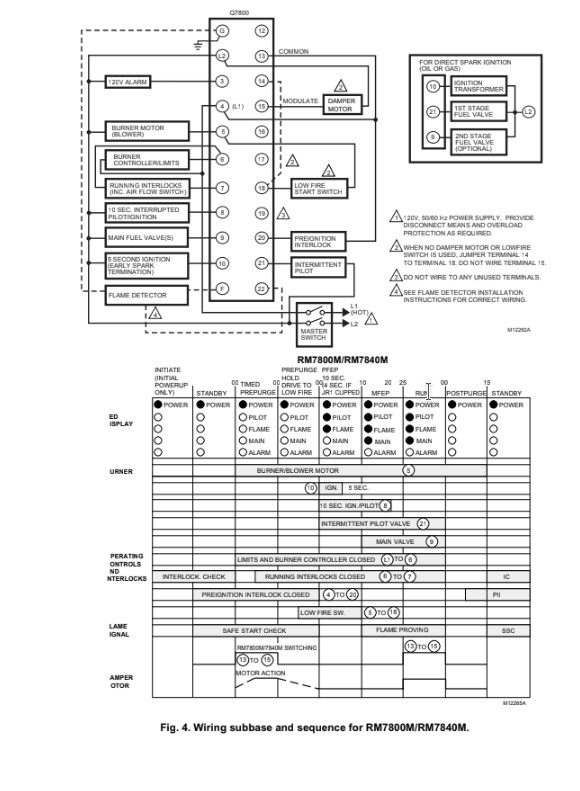

- Wiring connections for the relay modules are unique; therefore, refer to Fig. 2, 3, 4, or the correct Specifications for proper subbase wiring, and sequence charts.

- Wiring must comply with all applicable codes, ordinances and regulations.

- Wiring must comply with NEC Class 1 (Line Voltage) wiring.

- Loads connected to the RM7800/RM7840 must not exceed those listed on the RM7800/RM7840 label or the Specifications, see Table 1.

- Limits and interlocks must be rated to simultaneously carry and break current to the ignition transformer, pilot valve, and main fuel valve(s).

- All external timers must be listed or component recognized by authorities who have jurisdiction for the specific purpose for which they are used.

- For on-off gas-fired systems, some authorities who have jurisdiction prohibit the wiring of any limit or operating contacts in series between the flame safeguard control and the main fuel valve(s).

- Two Flame Detectors can be connected in parallel with the exception of Infrared Flame Detectors (C7075).

- This equipment generates, uses and can radiate radio frequency energy and, if not installed and used in accordance with the instructions, may cause interference to radio communications. It has been tested and found to comply with the limits for a Class B computing device of Part 15 of FCC rules which are designed to provide reasonable protection against such interference when operated in a commercial environment. Operation of this equipment in a residential area may cause interference; in which case, the users at their own expense may be required to take whatever measures are required to correct this interference.

- This digital apparatus does not exceed the Class B limits for radio noise for digital apparatus set out in the Radio Interference Regulations of the Canadian Department of Communications.

Location

Humidity

Install the relay module where the relative humidity never reaches the saturation point. The relay module is designed to operate in a maximum 85 percent relative humidity continuous, noncondensing, moisture environment. Condensing moisture may cause a safety shutdown.

Vibration

Do not install the relay module where it could be subjected to vibration in excess of 0.5G continuous maximum vibration.

Weather

The relay module is not designed to be weather tight. When installed outdoors, protect the relay module using an approved weather-tight enclosure.

Mounting Wiring Subbase

- Mount the subbase in any position except horizontally with the bifurcated contacts pointing down. The standard vertical position is recommended. Any other position decreases the maximum ambient temperature rating.

- Select a location on a wall, burner or electrical panel. The Q7800 can be mounted directly in the control cabinet. Be sure to allow adequate clearance for servicing, installation, access or removal of the RM7800/RM7840, Expanded Annunciator, Keyboard Display Module, flame amplifier, flame amplifier signal voltage probes, Run/Test Switch, electrical signal voltage probes and electrical field connections.

- For surface mounting, use the back of the subbase as a template to mark the four screw locations. Drill the pilot holes.

- Securely mount the subbase using four no. 6 screws.

Wiring Subbase

Electrical Shock Hazard: Can cause serious injury, death or equipment damage. Disconnect the power supply before beginning installation to prevent electrical shock, equipment and control damage. More than one power supply disconnect may be required.

- For proper subbase wiring, refer to Figs. 2, 3, 4 or 5.

- For proper remote wiring of the Keyboard Display Module, through a 203541 5-wire Connector, refer to the Specifications for the Keyboard Display Module (65-0090), Network Interface Unit (63-2278), Data ControlBus Module™ (65-0091) or Extension Cable Assembly (65-0131).

- Disconnect the power supply from the main disconnect before beginning installation to prevent electrical shock and equipment damage. More than one disconnect may be required.

- All wiring must comply with all applicable electrical codes, ordinances and regulations. Wiring, where required, must comply with NEC, Class 1 (Line Voltage) wiring.

- Recommended wire size and type: see Table 1.

- Recommended grounding practices: see Table 2. The Keyboard Display Module, Data ControlBus Module™ (for remote mounting or communications), through a 203541 5-wire Connector, or Communication Interface ControlBus Module must be wired in a daisy chain configuration, (1(a)-1(a), 2(b)-2(b), 3(c)-3(c}). The order of interconnection of all the devices listed above is not important. Be aware that modules on the closest and farthest end of the daisy chain configuration string require a 120 ohm (1/4 watt minimum) resistor termination across terminals 1 and 2 of the electrical connectors, for connections over 100 feet.

- Recommended wire routing of lead wires:

- Do not run high voltage ignition transformer wires in the same conduit with the flame detector, Data Control bus Module™, or Remote Reset Module wiring.

- Do not route flame detector, Data Control bus Module™, or Remote Reset Module lead wires in conduit with line-voltage circuits.

- Enclose flame detector lead wires without armor cable in metal cable or conduit.

- Follow directions in the flame detector, Data Control bus Module™, or Remote Reset Module Instructions.

- Keyboard Display Module (KDM): Because the KDM is powered from a low voltage, energy limited source, it can be mounted outside of a control panel if it is protected from mechanical damage.

NOTE: A 13 Vdc power supply must be used any time more than one Keyboard Display Module is used.

- Maximum wire lengths follow:

- RM7800/RM7840 leadwires—The maximum length of the lead wire is 300 feet to terminal inputs (Control, Preignition Interlock, Running/Lockout Interlock, High Fire Switch, and Low Fire Switch).

- Flame Detector leadwires—The maximum flame sensor leadwire length is limited by the flame signal strength.

- Remote Reset leadwires—The maximum length of wire is 1000 feet to a Remote Reset pushbutton.

- Data Controlbus Module™—The maximum Data Control bus Module™ cable length depends on the number of system modules connected, the noise conditions, and the cable used. The maximum length of all Data Controlbus Module™ interconnecting wire is 1000 feet.

- Make sure loads do not exceed the terminal ratings. Refer to the label on the RM7800/RM7840 or to the ratings in Tables 3, 4 and 5.

Final Wiring Check

- Check the power supply circuit. The voltage and frequency tolerance must match those of the M7800/RM7840. A separate power supply circuit may be required for the RM7800/RM7840. Add the required disconnect means and overload protection.

- Check all wiring circuits and complete the Static Checkout, see Table 8, before installing the M7800/RM7840 on the subbase.

- Install all electrical connectors.

- Restore power to the panel.

Table 1. Recommended Wire Sizes and Part Numbers.

| Application | Recommended Wire Size | Recommended Part Number(s) |

| Line voltage terminals | 14, 16 or 18 AWG copper conductor, 600 volt insulation, moisture-resistant wire. | TTW60C, THW75C, THHNS0C. |

| Keyboard Display Module (KDM) | 22 AWG two-wire twisted pair with ground, or five wire. | Belden 8723 shielded cable or equivalent. |

| Data ControlBus Module™ | 22 AWG two-wire twisted pair with ground, or five wire | Belden 8723 shielded cable or equivalent. |

| Remote Reset Module | 22 AWG two-wire twisted pair, insulated for low voltage. | —– |

| Communications Interface ControlBus™ Module | 22 AWG two-wire twisted pair with ground. | Belden 8723 shielded cable or equivalent. |

| 13 Vdc full-wave rectified transformer power input. | 18 AWG wire insulated for voltages and temperatures for given application. | TTW60C, THW75C, THHN90C. |

Table 2. Recommended Grounding Practices.

| Ground Type | Recommended Practice |

| Earth ground (subbase and relay module). | Use to provide a connection between the subbase and the control panel of the equipment. Earth ground must be capable of conducting enough current to blow the 20A fuse (or breaker) in the event of an internal short circuit. Use wide straps or brackets to provide minimum length, maximum surface area ground conductors. If a leadwire must be used, use 14 AWG copper wire. Make sure that mechanically tightened joints along the ground path are free of nonconductive coatings and protected against corrosion on mating surfaces. |

| Signal ground (KDM, Data ControlBus Module™, Communications Interface ControlBus™ Module). | Use the shield of the signal wire to ground the device to the signal ground terminals [3(c)] of each device. Connect the shield at both ends of the chain to earth ground. |

Table 3. Terminal Ratings.

| Terminal No. | Description | Ratings |

| G | Flame Sensor Ground | — |

| Earth G | Earth Ground | — |

| LN(2) | Line Voltage Common | — |

| 3 | Alarm | 120 Vac. 1A pilot duty. |

| 4 | Line Voltage Supply (L1) | 120 Vac (+10%/-15%), 50 or 60 Hz (+10%)b.d |

| 5 | Burner Motor | 120 Vac, 9.8 AFL, 58.8 ALR (inrush). |

| 6 | Burner Controller and Limits | 120 Vac, 1 mA. |

| 7 | Lockout/Running Interlock | 120 Vac, 8A run, 43A inrush. |

| 8 | Pilot Valve/ignition | 120 Vac. |

| 9 | Main Fuel Valve | 120 Vac. |

| 10 | Ignition | 120 Vac. |

| F(11) | Flame Sensor | 60 to 220 Vac, current limited. |

| 12 | Firing Rate High Fire | 120 Vac, 75 VA pilot duty. |

| 13 | Firing Rate Common | 120 Vac, 75 VA pilot duty. |

| 14 | Firing Rate Low Fire | 120 Vac, 75 VA pilot duty. |

| 15 | Firing Rate Modulate | 120 Vac, 75 VA pilot duty. |

| 16 | Firing Rate Modulate | — |

| 17 | Firing Rate Modulate | — |

| 18 | Low Fire Switch Input | 120 Vac, 1 mA. |

| 19 | High Fire Switch Input | 120 Vac, 1 mA. |

| 20 | Preignition Interlock Input | 120 Vac, 1 mA. |

| 21 | Interrupted/Intermittent Pilot Valve/First Stage Oil Valve | 120 Vac, 1 mA. |

| 22 | Shutter | 120 Vac, 0.5A. |

The relay module must have an earth ground providing a connection between the subbase and the control panel or the equipment. The earth ground wire must be capable of conducting the current to blow the 15A fuse (or breaker) in event of an internal short circuit. The relay module requires a low impedance ground connection to the equipment frame, which, in turn, requires a low impedance connection to earth ground.

2000 VA maximum connected load to relay module assembly.

See tables 4 and 5.

RM7800G,M/RM7840G,M operating frequency determined by relay module selection.

Table 4. Combinations for Terminals 8, 9, 10 and 21.

| Combination No. | Pilot Fuel 8 | Main 9 | Ignition 10 | Intermittent Pilot Valve 21 |

| 1 | C | F | No Load | No Load |

| 2 | B | F | No Load | No Load |

| 3 | No Load | F | No Load | B |

| 4 | F | F | A | No Load |

| 5 | No Load | F | A | F |

| 6 | D | F | A | No Load |

| 7 | No Load | D | A | D |

| 8 | D | D | A | No Load |

| 9 | No Load | D | A | D |

Table 5. Explanation of Each Combination.

| A | B | C | D | E |

| 4.5A ignition. | 50 VA Pilot Duty plus4.5A ignition. | 180 VA ignition plus motor valve with: 660 VA inrush, 360 VA open, 260 VA hold. | 2A Pilot Duty. | 64 VA Pilot Duty plus motor valves with:3850 VA inrush, 700 VA open, 250 VA hold. |

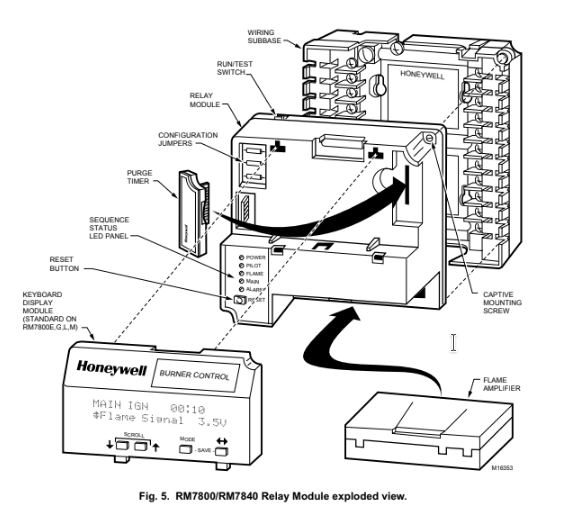

Mounting RM7800/RM7840 Relay Module (Fig. 5)

- Mount the RM7800/RM7840 vertically on the Q7800 Subbase, or mount horizontally with the knife blade terminals pointing downward. When mounted on the Q7800A, the RM7800/RM7840 must be in an electrical enclosure.

- When mounting in an electrical enclosure, provide adequate clearance for servicing, installation and removal of the RM7800/RM7840, Keyboard Display Module, flame amplifier, flame amplifier signal voltage probes and electrical connections.

- Allow an additional two inches below the RM7800/RM7840 for the flame amplifier mounting.

- Allow an optional three-inch minimum to both sides of the RM7800/RM7840 for electrical signal voltage probes.

- Make sure no subbase wiring is projecting beyond the terminal blocks. Tuck in wiring against the back of the subbase so it does not interfere with the knife blade terminals or bifurcated contacts.

IMPORTANT: The RM7800/RM7840 must be installed with a plug-in motion rather than a hinge action.

- Mount the RM7800/RM7840 by aligning the four L-shaped corner guides and knife blade terminals with the bifurcated contacts on the wiring subbase and securely tighten the two screws without deforming the plastic.

Fig. 3. Wiring subbase and sequence for RM7800G/RM7840G.

Fig. 4. Wiring subbase and sequence for RM7800M/RM7840M.

Fig. 5. RM7800/RM7840 Relay Module exploded view.

SAFETY SHUTDOWN

Safety Shutdown (Lockout) occurs if any of the following occur during the indicated period:

1. INITIATE Period:

- Purge card is not installed or is removed.

- Purge card is bad.

- Configuration jumpers are changed (after 200 hours of operation).

- Ac line power errors occurred, see Operation section.

- Four minute INITIATE period has been exceeded.

2. STANDBY Period:

- Flame signal is present after 40 seconds.

- Preignition Interlock is open an accumulative time of 30 seconds.

- Interlock check feature is enabled and the Interlock String (including airflow switch) is closed for 120 seconds with controller closed.

- Ignition/pilot valve/intermittent pilot valve terminal is energized.

- Main valve terminal is energized.

- Internal system fault occurred.

- Purge card is not installed or is removed.

- Purge card is bad.

3. PREPURGE Period:

- Preignition Interlock opens anytime during PREPURGE period (RM7840E,L).

- Flame signal is detected after first ten seconds during PREPURGE (RM7840E,L).

- High Fire Switch fails to close within four minutes and fifteen seconds after the firing rate motor is commanded to drive to the high fire position at the start of PREPURGE (RM7840E,L).

- Low Fire Switch fails to close within four minutes and fifteen seconds after the firing rate motor is commanded to drive to the low fire position at the end of PREPURGE.

- Running Interlock does not close within 30 seconds (RM7840G,M).

- Lockout Interlock does not close within 10 seconds (RM7840E,L).

- Lockout Interlock opens during PREPURGE (RM7840E,L).

- Ignition/pilot valve/intermittent pilot valve terminal is energized.

- Main valve terminal is energized.

- Internal system fault occurred.

- Purge card is removed.

- Purge card is bad.

4. PILOT FLAME ESTABLISHING Period (PFEP):

- Low Fire Switch opens.

- Lockout Interlock opens (RM7840E,L).

- Ignition/pilot valve/intermittent pilot valve terminal is not energized.

- Early spark termination terminal is energized after five seconds.

- No flame is present at the end of PFEP.

- Main valve terminal is energized (RM7800G,M).

- Internal system fault occurred.

- Purge card is removed.

- Purge card is bad.

5. MAIN FLAME ESTABLISHING Period (MFEP):

- Low Fire Switch Opens.

- Lockout Interlock opens (RM7840E,L).

- Ignition/pilot valve/intermittent pilot valve terminal is not energized.

- Main valve terminal is not energized.

- No flame is present at the end of MFEP.

- Internal system fault occurred.

- Purge card is removed.

- Purge card is bad.

6. RUN Period:

- No flame is present.

- Lockout Interlock opens (RM7840E,L).

- Interrupted pilot valve terminal is energized (RM7840G,M).

- Main valve terminal is not energized.

- Internal system fault occurred.

- Purge card is removed.

- Purge card is bad.

7. POSTPURGE Period:

- Preignition Interlock does not close in five seconds and opens after five-second time period.

- Ignition/pilot valve/intermittent pilot valve terminal is energized.

- Main valve terminal is energized.

- Internal system fault occurred.

- Purge card is removed.

- Purge card is bad.

OPERATION

Sequence of Operation

The RM7800/RM7840 has the following operating sequences, see Fig. 2, 3, 4, and Table 6. The RM7800/RM7840 LED provide positive visual indication of the program sequence: POWER, PILOT, FLAME, MAIN and ALARM.

Initiate

The RM7800/RM7840 enters the INITIATE sequence when the Relay Module is powered. The RM7800/RM7840 can also enter the INITIATE sequence if the Relay Module verifies voltage fluctuations of +10/-15 percent or frequency fluctuations of +/-10 percent during any part of the operating sequence. The INITIATE sequence lasts for ten seconds unless the voltage or frequency tolerances are not met. When the tolerances are not met, a hold condition is initiated and displayed on the VFD for at least five seconds. When the tolerances are met, the INITIATE sequence restarts. If the condition is not corrected and the hold condition exists for four minutes, the RM7800/RM7840 locks out. Causes for hold conditions in the INITIATE sequence:

- AC line dropout is detected.

- AC line frequency error occurs caused by using a 60 Hz device on a 50 Hz line, or vice versa.

- AC line noise prevents a sufficient reading of the line voltage inputs.

- Low line voltage brownouts occur.

The INITIATE sequence also delays the burner motor starter from being energized and de-energized from an intermittent AC line input or control input.

Standby

The RM7800/RM7840 is ready to start an operating sequence when the operating control determines a call for heat is present. The burner switch, limits, operating control and all microcomputer monitored circuits must be in the correct state for the RM7800/RM7840 to continue into the PREPURGE sequence.

Normal Start-Up Prepurge

The RM7800/RM7840 provides a prepurge timing selectable from two seconds to 30 minutes with power applied and the RM7800 operating control indicating a call for heat:

- Running Interlocks, Preignition Interlocks, Burner Switch, Run/Test Switch, Lockout Interlocks and all microcomputer monitored circuits must be in the correct operating state.

- The blower motor output, terminal 5, is powered to start the PREPURGE sequence, except for the RM7800E/RM7840. The firing rate motor is driven to the high fire position. The PREPURGE timing for the RM7800/RM7840E,L does not begin until the Lockout Interlock String and High Fire Switch are both closed. The blower motor output for the RM7800E is not energized until the High Fire Switch is closed.

- The Preignition Interlock input must remain closed throughout PREPURGE; otherwise, control returns to the STANDBY state and holds (30 seconds) for the RM7800/RM7840G,M or safety shutdown for the RM7800/RM7840E,L occurs.

- The Lockout Interlock or Running Interlock inputs (interlock circuit including Airflow Switch) must close by ten seconds into PREPURGE; otherwise, a recycle to the beginning of PREPURGE for the RM7800/RM7840G,M will happen or a safety shutdown for the RM7800/RM7840E,L occurs.

- When PREPURGE timing is complete, the firing rate motor drives to the low fire position, RM7800/RM7840E,G,L.

- When the firing rate motor reaches low fire position, the Low Fire Switch, terminal 18, input must be energized before entering the Ignition Trial state.

Ignition Trials

- Pilot Flame Establishing Period (PFEP):

- With the firing rate motor at the low fire position:

- The pilot valve and ignition transformer,terminals 8, 10 and 21, are energized. The RM7800M has an intermittent pilot valve, terminal 21. The RM7800/RM7840G has an interrupted or intermittent pilot valve, terminal 21, depending on the selection of configurationJumper 2. The RM7800/RM7840E,L has a fifteen-second interrupted pilot valve, terminal 21. All of the RM7800/RM7840s have a ten-second interrupted pilot valve/ignition, terminal 8.

- During PFEP, the Low Fire Switch must remain closed. If it opens, a safety shutdown occurs.

- The Preignition Interlock input is ignored throughout the Ignition Trial state.

- Flame must be proven by the end of the ten-second PFEP (four if JR1 is clipped) to allow the sequence to continue. If flame is not proven by the end of PFEP, a safety shutdown occurs.

- After five seconds, the ignition, terminal 10, is de-energized for early spark termination.

- With the firing rate motor at the low fire position:

- Main Flame Establishing Period (MFEP):

- Terminal 9 is energized when the presence of flame is verified at the end of a 10-second Pilot Flame Establishing Period (PFEP) (four seconds if JR1 is clipped).

- Terminal 8 is turned off 10 seconds after Terminal 9 is energized.

- Terminal 21 action:

- RM7800E,L/RM7840E,L: De-energized 15 seconds after Terminal 9 is energized.

- RM7840G:

- Not turned off, or

- (b)15 seconds after Terminal 9 is energized and JR2 is clipped, or

- (c)30 seconds after Terminal 9 is energized and Terminals 5 and 19 are jumpered and jumper JR2 is clipped.

- RM7800L1053, RM7840L1026, RM7800M/RM7840M: Remain energized as long as call for heat is present.

Run

- A ten-second stabilization period occurs at the beginning of the RUN period.

- The firing rate motor releases to modulation (RM7800/RM7840E,G,L). Damper motor is energized (RM7800/RM7840M).

- 3. The RM7800/RM7840 is now in RUN and remains in RUN until the controller input, terminal 6, opens, indicating that the demand is satisfied or a limit opened.

Postpurge

The RM7800/RM7840 provides a fifteen-second POSTPURGE following the completion of the RUN period.

The blower motor output is powered to drive all products of combustion and any unburned fuel from the combustion chamber. It also supplies combustion air to burn fuel being purged from the fuel line downstream of the fuel shutoff valve.

- The main fuel valve and intermittent pilot valve, Terminals 9 and 21, are de-energized and the firing rate motor is commanded to the low fire position to begin the POSTPURGE period.

- The Preignition Interlock closes within the first five seconds of POSTPURGE.

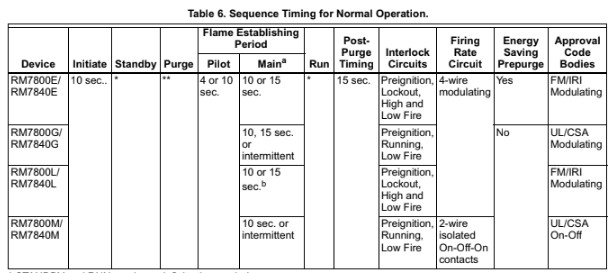

Table 6. Sequence Timing for Normal Operation.

* STANDBY and RUN can be an infinite time period.

**PURGE determined by which ST7800A purge card is selected.

The MFEP is determined by which terminal is used, configuration jumper selected or jumper wire added. See Fig. 2, 3, 4, 5 and 6.

RM7800L1053, RM7840L1026: 10 second or intermittent.

Keyboard Display Module (VFD)

The Keyboard Display Module (see Fig. 5) is provided with the RM7800 Relay Module (but is not required for operation) and is an option for the RM7840 Relay Module. The first line of the Vacuum Fluorescent Display (VFD) provides:

- Current status of the burner sequence (STANDBY, PURGE, PILOT IGN, MAIN IGN, RUN and POSTPURGE).

- Timing information (PURGE, PILOT IGN, MAIN IGN and POSTPURGE) in minutes and seconds.

- Hold information (PURGE HOLD: T19).

- Lockout information (Lockout, Fault Code, Message and Sequence).

The extreme right side of the first line is either blank or shows a small arrow pointing to the second line followed by a two-letter code (DI-Diagnostic Information,

Hn-Fault History Information, and EA-Expanded Annunciator). When the arrow and two-letter code are displayed, it indicates the second line is showing a selectable message submenu. The second line displays selectable or preemptive messages.

A selectable message supplies information for flame strength, system status indication, system or self-diagnostics and troubleshooting.

A preemptive message has parentheses around the message and supplies a detailed message to support the sequence status information. A preemptive message can also be a lockout message. A preemptive message replaces a selectable message to support the sequence status information. It also replaces a selectable message after 60 seconds if it or a lockout message is available.

Run/Test Switch

WARNING

Explosion Hazard.

Can cause serious injury or death.

Do not use the Run/Test switch during the Pilot Flame Establishing Period for the RM7800/RM7840G,M when using Direct Spark Function, because it turns on the main gas valve, causing an accumulation of fuel in the burner.

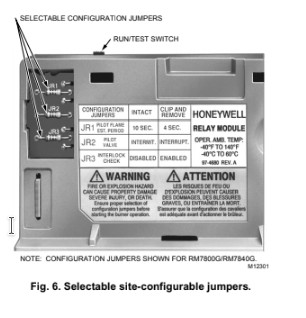

The Run/Test Switch is located on the top side of the RM7800/RM7840, see Fig. 6. The Run/Test Switch allows the burner sequence to be altered as follows:

- In Prepurge Drive To High Fire Position, the Run/Test Switch, when placed in the TEST position, holds in PREPURGE with the firing rate motor in the High Fire position.

- In the measured PREPURGE sequence, the Run/Test Switch, when placed in the TEST position, causes the PREPURGE timing to stop. The firing rate motor is in the High Fire position.

- In Prepurge Drive to Low Fire position, the Run/Test Switch, when placed in the TEST position, holds the burner sequence in PREPURGE with the firing rate motor in the Low Fire position.

- In PFEP, the Run/Test Switch, when placed in the TEST position, stops the timer during the first eight seconds when a ten second PFEP is selected or during the first three seconds when a four second PFEP is selected, allowing pilot-turn-down test and other burner adjustments to be made. This activates a fifteen second flameout timer that permits pilot flame adjustment without nuisance safety shutdowns. The Run/Test Switch is ignored during PFEP for the RM7800/ RM7840E,L if Terminals 8 and 9 or 9 and 21 are jumpered.

- During Run, the Run/Test Switch, when placed in the TEST position, drives the firing rate motor to the Low Fire position.

NOTE: When RM7800/RM7840 is switched to the Test mode, it stops and holds at the next Run/Test Switch point in the operating sequence. Make sure that the Run/Test Switch is in the RUN position before leaving the installation.

SETTINGS AND ADJUSTMENTS

Selectable Site-Configurable Jumpers

The RM7800/RM7840 has three site-configurable jumper options, see Fig. 6 and Table 7. If necessary, clip the site-configurable jumpers with side cutters and remove the resistors from the Relay Module.

NOTE: CONFIGURATION JUMPERS SHOWN FOR RM7800G/RM7840G.

Fig. 6. Selectable site-configurable jumpers.

Table 7. Site Configurable Jumper Options.

| Jumper Number | Description | Intact | Clipped | RM7800/RM7840 Type |

| JR1 | Pilot Flame Establishing Period (PFEP) | 10 seconds | 4 seconds | All |

| JR2 | Pilot Valve/Main Flame Establishing Period (MFEP) | 10 seconds Intermitent | 15 or 30 seconds Interrupted | RM7800/RM7840 |

| JR3 | Start-up Interlock Check | Disabled | Enabled | All |

Pilot Valve /First Stage Oil Valve (Valve/Start) Terminal 21.

A 30 second MFEP can be accomplished by adding a jumper wire between Terminals 19 and 5.

SERVICE NOTE: Clipping and removing a site-configurable jumper enhances the level of safety. Removal after 200 hours of main valve operation will result in a hard lockout, Code 110.

STATIC CHECKOUT

After checking all wiring, perform this checkout before installing the RM7800/RM7840 on the subbase. These tests verify the Q7800 Wiring Subbase is wired correctly, and the external controllers, limits, interlocks, actuators, valves, transformers, motors and other devices are operating properly.

WARNING

Explosion and Electrical Shock Hazard.

Can cause serious injury, death or equipment damage.

- Close all manual fuel shutoff valve(s) before starting these tests.

- Use extreme care while testing the system. Line voltage is present on most terminal connections when power is on.

- Open the master switch before installing or removing a jumper on the subbase.

- Before continuing to the next test, be sure to remove test jumper(s) used in the previous test.

- Replace all limits and interlocks that are not operating properly. Do not bypass limits and interlocks.

CAUTION

Equipment Damage Hazard.

Improper testing can damage equipment.

Internal surge protectors can break down and conduct a current, causing the RM7800/RM7840 to fail the dielectric test or possibly destroy the internal lightning and high current protection. Do not perform a dielectric test with the RM7800/RM7840 installed.

Equipment Recommended

- Voltmeter (1M ohm/volt minimum sensitivity) set on the 0-300 Vac scale.

- Two jumper wires; no. 14 wire, insulated, 12 inches (304.8 mm) long with insulated alligator clips at both ends.

General Instructions

- Perform all applicable tests listed in Static Checkout, Table 8, in the order listed.

- Make sure all manual fuel shutoff valve(s) are closed.

- Perform only those tests designated for the specific RM7800/RM7840 model being tested.

- Raise the setpoint of the operating controller to simulate a call for heat.

- For each test, open the master switch and install the jumper wire(s) between the subbase wiring terminals listed in the Test Jumpers column.

- Close the master switch before observing operation.

- Read the voltage between the subbase wiring terminals listed in the Voltmeter column.

- If there is no voltage or the operation is abnormal, check the circuits and external devices as described in the last column.

- Check all wiring for correct connections, tight terminal screws, correct wire, and proper wiring techniques. Replace all damaged or incorrectly sized wires.

- Replace faulty controllers, limits, interlocks, actuators, valves, transformers, motors and other devices as required.

- Make sure normal operation is obtained for each required test before continuing the checkout.

- After completing each test, be sure to remove the test jumper(s).

WARNING

Explosion Hazard.

Can cause serious injury or death.

Make sure all manual fuel shutoff valves are closed before performing static checkout.

Table 8. Static Checkout.

| Test no. | RM7800/ RM7840 Models | Test Jumpers | Voltmeter | Normal Operation | If Operation is Abnormal, Check the Items Listed Below |

| 1 | All | None | 4-L2 | Line voltage at Terminal 4 | 1. Master Switch.2. Power connected to the Master Switch.3. Overload protection (fuse, circuit breaker, etc.) has not opened the power line. |

| 2 | 6-L2 | Line voltage at Terminal 6 | 1. Limits.2. Burner Controller. | ||

| 3 | 20-L2 | Line voltage at Terminal 20 | 1. Preignition interlocks. | ||

| 4 | 4-5 | 7-L2 | 1. Burner motor (fan or blower) starts.2. Line voltage at Terminal7 within 10 seconds. | 1. Burner motor circuit.Manual switch of burner motor.Burner motor power supply, overload protection, and starter.Burner motor.2. Running or Lockout Interlocks (including Airflow Switch). | |

| 5 | 4-10 | – | Ignition spark (if ignition transformer is connected to Terminal 10) | 1. Watch for spark or listen for buzz. a. Ignition electrodes are clean.b. Ignition transformer is okay. | |

| 6 | All | 4-8 | – | 1. Ignition spark (if ignition transformer is connected to Terminal 8).2. Automatic pilot valve opens (if connected to Terminal 8). NOTE: Refer to wiring diagram of system being tested. | 1. Watch for spark or listen for buzz. a. Ignition electrodes are clean.b. Ignition transformer is okay. 2. Listen for click or feel head of valve for activation.a. Actuator if used.b. Pilot valve. |

| 7 | 4-21 | – | Same as test no. 6 for connections to Terminal 8. If using direct spark ignition, check the first stage fuel valve(s) instead of the pilot valve. | Same as test no. 6. If using direct spark ignition, check the first stage fuel valve(s) instead of the pilot valve. | |

| 8 | 4-9 | – | Automatic main fuel valve(s) open. If using direct spark ignition on a model with intermittent pilot on Terminal 21, check the optional second stage fuel valve, if used. | 1. Listen for and observe operation of the main fuel valve(s) and actuator(s). 2. Valve(s) and actuator(s). | |

| 9 | 4-3 | – | Alarm (if used) turns on. | 1. Alarm. | |

| 10 | RM7800E,G,L; RM7840E,G,L | 4-5 and 12-13 | 18-L2 | Firing rate motor drives open; zero volts at Terminal 18 after motor starts driving open. | 1. Low Fire Start Switch. 2. Firing rate motor and transformer. |

| 11 | RM7800E,G,L; RM7840E,G,L | 4-5 and 14-13 | 18-L2 | Firing rate motor drives closed; line voltage at Terminal 18 after motor is in Low Fire position. | 1. Low Fire Start Switch. 2. Firing rate motor and transformer. |

| 12 | RM7800E,L; RM7840E,L | 4-5 and 12-13 | 19-L2 | Firing rate motor drives open; line voltage at Terminal 19 after motor is in High Fire position. | 1. High Fire Purge Switch. 2. Firing rate motor and transformer. |

| 13 | RM7800E,L; RM7840E,L | 4-5 and 14-13 | 19-L2 | Firing rate motor drives closed; zero volts at Terminal 19 after motor starts driving closed. | 1. Low Fire Start Switch. 2. Firing rate motor and transformer. |

| 14 | RM7800E,G,L; RM7840E,G,L | 15-13 | – | 1. Raise setpoint of Series 90 1. Series 90 Controller—firing rate motor should drive toward open. 2. Lower setpoint of Series 90 controller—firing rate motor should drive toward closed. | 1. Series 90 Controller 2. Firing rate motor and transformer. |

| 15 | RM7800M;RM7840M with open damper contacts.. | 14-13 | – | If damper motor is used, motor drives damper open. | Damper motor. |

| 16 | RM7800M;RM7840M with open damper contacts.. | 4-5 | 18-L2 | If damper motor is used, motor drives damper open; line voltage at terminal 18 after motor is in Low Fire Position. | Low Fire Start Switch. Damper motor. |

| 17 | RM7800M;RM7840M with open damper contacts.. | 4-5And4-13 | 18-L2 | If damper motor is used, motor drives damper open; zero volts at Terminal 18. | Low Fire Start Switch. Damper motor. |

CAUTION

Equipment Damage Hazard.

Improper wiring can damage equipment.

On completing these tests, open the master switch and remove all test jumpers from the subbase terminal. Also remove bypass jumpers from the low fuel pressure limits (if used) to prevent equipment damage.

Automation and Control Solutions

Honeywell

1985 Douglas Drive North

Golden Valley, MN 55422

Honeywell Limited-Honeywell Limitée

35 Dynamic Drive

Scarborough, Ontario

MIV 429

www.honeywell.com

You can download the complete PDF version of this user manual here.