Planning and design

WHY INSTALL AN UNDERGROUND IRRIGATION SYSTEM

- Conserve Water & Money — reduce over-watering and water when evaporation levels are low.

- Save Time — enjoy a beautiful yard and spend more time doing the things you like.

- Increase Property Value — Greener, thicker lawns, shrubs and trees, make your property more attractive.

- Eliminate Yard Clutter — eliminates the ugly tangle and yellow marks left by unsightly garden hose.

READ ALSO: MORTON MOTORIZED WATER SHUTOFF VALVE USER’S MANUAL

CHECK LOCAL CODES

Water District

Call your local water district for requirements concerning permits, plumbers, backflow prevention and pipe requirements.

Common Questions To Ask Your Water District:

- Is a permit required? Yes No

- Is a licensed plumber required for connecting to the main water supply? Yes No

- What type of backflow prevention device is required?

Double Check Pressure Vacuum Breaker

Automatic Anti-siphon Valve Dual Check Valve

- Climate: Will pipes freeze in my area?

Freezing Non Freezing

- How deep should | bury my pipes?

Pipe Depth

- What type of pipe is required (or recommended) for my area?

Pipe type:

Utility Companies

Before digging, contact your local gas, power, telephone, and cable companies to mark underground cables and pipelines on your property, such as:

Gas power other

Phone TV & Internet cables

MEASURE WATER FLOW

You need to determine the available water flow for your sprinkler system so you’ll know how many sprinkler heads can run at one time. Water flow is measured in gallons per minute or GPM.

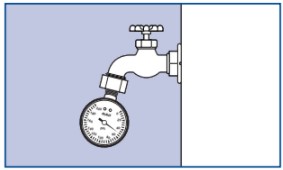

Measure Your Water Pressure

- Attach an Orbit pressure gauge (part # 53020, 91130) to an unregulated outside faucet*. Unregulated means a line without a pressure regulator.

- Open the faucet and record the reading on the gauge. No water should be running during the test.

PSI—-

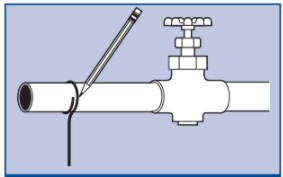

Measure the Main Water Service Line

- Wrap a piece of string around your main water service line then measure the length of the string.

- Use the table to convert the string length to pipe size (diameter).

Note: The main water service line is the pipe that runs from the water meter to the house. If you’re connecting to a line other than the main line, measure the line that you will be connecting to.

DETERMINE SIZE OF SERVICE LINE

| Length of string “ | 2″ | 2-3/4″ | 3-1/4″ | 3-1/2″ | 4-1/4 |

| Copper pipe size | 1/2″ | 3/4″ | 1” | ||

| PVC or galvanized pipe size | 1/2″ | 3/4″ | 1” |

System Capacity

Use the main line pipe size and pressure (PSI) taken to determine the gallons per minute (GPM) capacity of your system.

Water pressure (PSI)

| Main line size | 35 LB. | 40 LB. | 45 LB. | 50LB. | 55LB. | 60LB. | 65LB. | 70LB| | 75 LB |

| ½” | 3.5 | 5.0 | 6.0 | 6.5 | 7.0 | 7.5 | 8.0 | 9.0 | 9.5 |

| ¾” | 7.5 | 9.0 | 10.0 | 12.0 | 13.0 | 14.0 | 15.0 | 16.0 | 17.5 |

| 1” | 10.0 | 11.5 | 13.5 | 15.0 | 16.0 | 17.5 | 18.5 | 20.0 | 21.0 |

* If an unregulated faucet is unavailable, call the local water district for an estimated PSI.

Important: If your water pressure exceeds 80 PSI, use a pressure reducer. Excessive pressure may damage system.

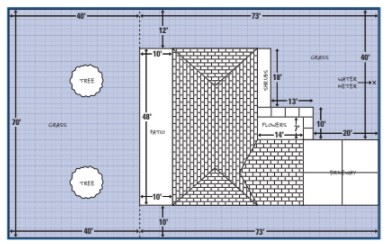

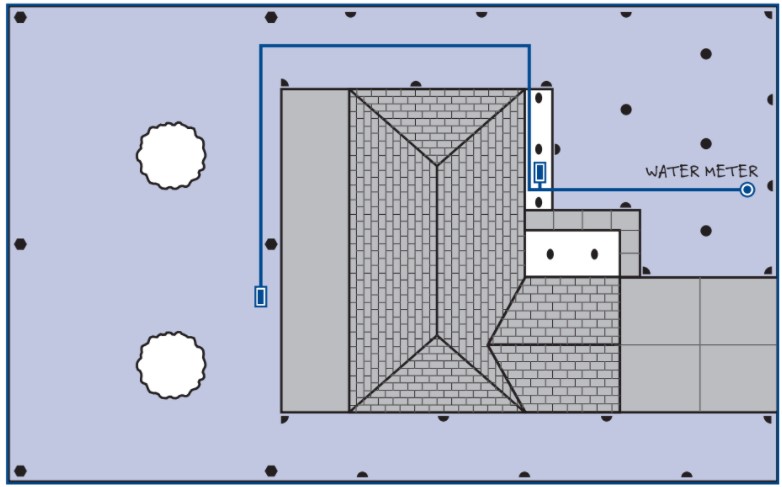

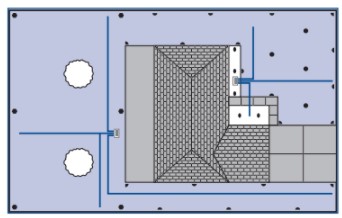

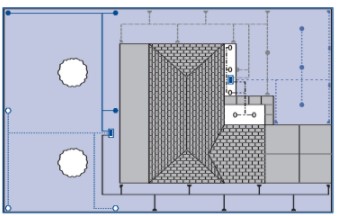

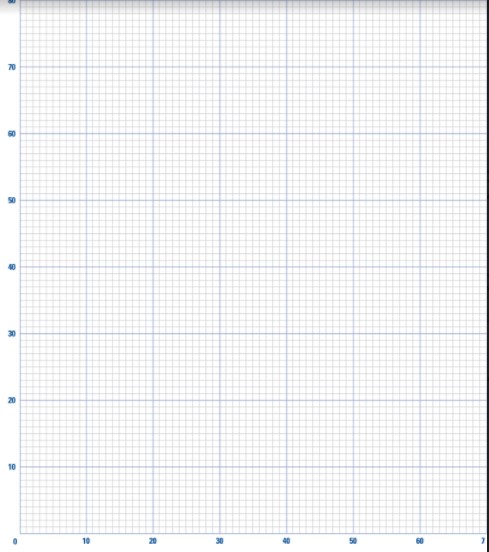

MEASURE & DRAW PROPERTY

Measure your property and create a top down view on graph paper (supplied in this guide).

Make the drawing to scale. For example, each one-inch square represents 10 feet on the graph paper, or each small square = 1 foot.

Draw Property to Scale.

Include:

: Buildings, sidewalks, patios, driveways and trees

Label:

Grass, flower beds and water meter location

LET ORBIT DESIGN YOUR SPRINKLER SYSTEM

Instead of continuing on to the next section, go to www.orbitonline.com and use the free sprinkler system design program.

What you receive:

- Detailed color-coded drawings with:

- Sprinkler placement and spray patterns

- Layouts of individual sprinkler zones/stations

- Valve and sprinkler pipe placement.

- Step by step assembly instructions.

- Detailed parts list for PVC or Poly-Pipe systems.

- Quick turnaround — Completed in about 2 days.

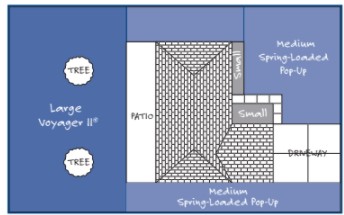

SELECT HEADS

Select sprinkler heads you would like to use for each area and make a note of each type on your drawing.

Select Head Type for Each Section

Sprinklers are generally divided into three categories:

- Large Area Sprinklers

Areas larger than 25′ x 25′

- Medium Area Sprinklers

Areas smaller than 25′ x 25′

- Small Area Sprinklers

Areas with flowers, shrubs, and ground cover

Note: Refer to page 22 (Selecting Your Products) to determine the best sprinkler for your yard.

Select Heads For Each Area

Our example uses:

- Voyager II in the back yard

- Spring-Loaded Pop-Up (with adjustable nozzle) in the front and side yard

- Mushroom bubblers in the front flower areas

Large Area Heads

For large open areas such as backyards and play areas. Space heads 15′ to 45′ apart (depending on sprinkler type).

- Gear Drive – Voyager II and Saturn III

– Easy to adjust

– Produces a smooth quiet rotating spray

– Closed case design resists clogging from grit, sand and heavy grasses

- Impact (Satellite? and 1/2″ Brass Impact)

– Simple and reliable flow-through design that utilizes an efficient impact mechanism

Medium Area Heads

Pop-up heads & Flush heads

Spacing: 10 to 15 feet

Commonly used in front and side yards

- Spring-Loaded Pop-Up with adjustable pattern

– Easy to adjust pattern 25° – 360°

- Spring-Loaded Pop-Up with fixed pattern

Medium Area Heads – Available in Full, 1/2, 1/4 and strip pattern nozzle

Small Area Heads

Stream & Bubbler heads

Spacing: 3 to 5 feet

Commonly used for flooding flower beds and ground cover or to spot water trees and shrubs.

- Mushroom Bubbler II”

- Adjustable flow

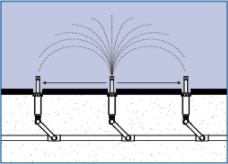

PLAN HEAD PLACEMENT

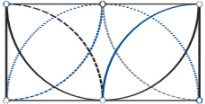

Head to Head Coverage

Proper sprinkler placement allows even watering and reduces dry patches.

Proper placement requires:

- Head to head coverage: Each sprinkler should spray to the head beside and across it.

- Equal spacing between heads: Permits uniform water distribution.

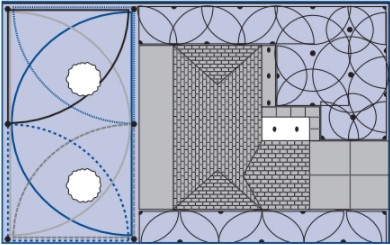

Placement Example: Good

- Good Overlap

- Head to head coverage

Placement Example: Bad

There is not enough overlap. The center is not getting water.

- Not enough overlap

- No coverage in center

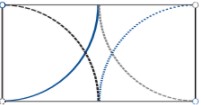

Narrow Strips

On narrow strips of grass use strip pattern spray heads and space them evenly apart.

These heads may be used for narrow strips up to 4 feet wide.

Evenly space strip heads on narrow sections.

Place Heads in Corners

- Begin by placing a sprinkler in each corner on your drawing.

- Use a compass to draw the spray pattern.

Note: Use chart 2 to obtain spray distance.

Add Heads and Adjust Spacing

- Add sprinklers along the sides or center to increase coverage.

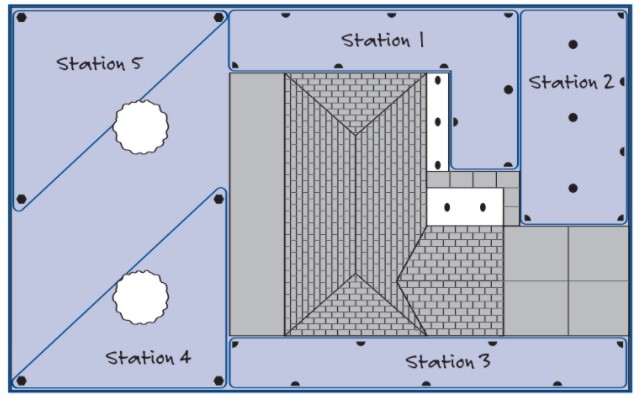

CREATING WATERING ZONES OR STATIONS

A watering zone or station consists of a group of sprinklers attached to one valve.

The number of heads per zone will be determined in this section.

Purpose of Zones

Zones are designed to:

- Maintain adequate water flow for optimal spray coverage (Avoid dry patches)

- Separate areas based on watering requirements

– Shade vs. Full Sun Areas

– Lawn vs. Shrubs

Important:

- Do not mix sprinkler types in the same zone (e.g. Gear Drive, Impacts, Pop-Ups and Bubblers)

- Do not exceed the maximum sprinkler heads recommended per zone

- Use the recommended pipe size in this guide. Smaller diameter pipe will decrease the water flow.

Group Heads of Same Type in the Same Area

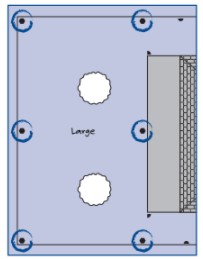

Starting with large area heads, use the following example as a guide.

- Identify all large area heads on your drawing.

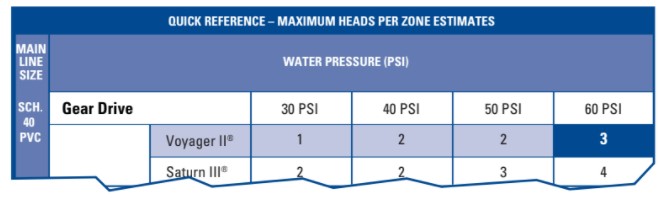

Divide Large Area Heads into Zones

STEP 1: Maximum Heads Per Zone

Use the following information (collected earlier) to determine zone capacity:

- Main Line Size

- Water Pressure (PSI)

- Large area head selected

Use Orbit’s Quick Reference (Chart 1) to determine the maximum heads per zone for your sprinkler system.

Example — We have determined that our home has a “Main Line” size of 3/4” with a “Static Water Pressure” of 60 psi. Based on this information, and using the Quick Reference, we see that we cannot use more than three Voyager II° sprinklers in the same zone.

STEP 2: Identifying Sprinklers in a Zone

Begin grouping large area heads; ensure you do not exceed your “Maximum Heads per zone number’

Example — Since we determined (in our example above) that 3 Voyager II° heads is the maximum zone capacity, we grouped all large area heads into 2 zones.

Step 3: Medium and Small Area Head Zones

Repeat steps 1 & 2 to determine and identify zones for Medium Areas Heads. Repeat again for Small Area Heads.

Step 4: Number Each Zone

- Assign a number to each zone.

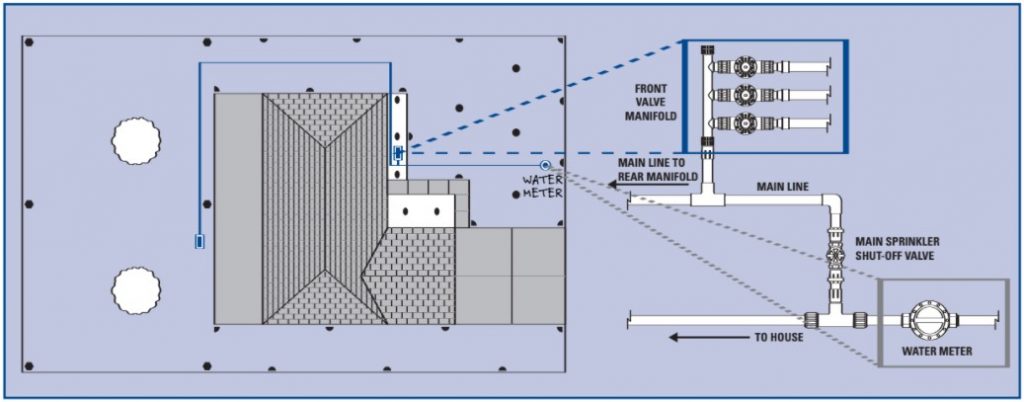

PLAN VALVE PLACEMENT

You’ll need to select a location for your main shut-off valve and the best location for the sprinkler valve manifold.

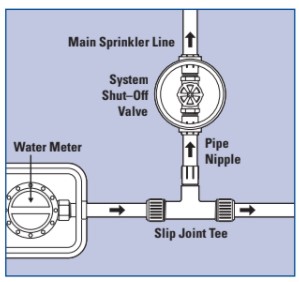

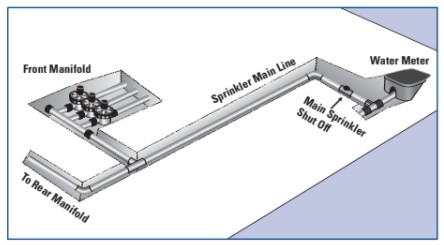

Main Shut-Off Valve

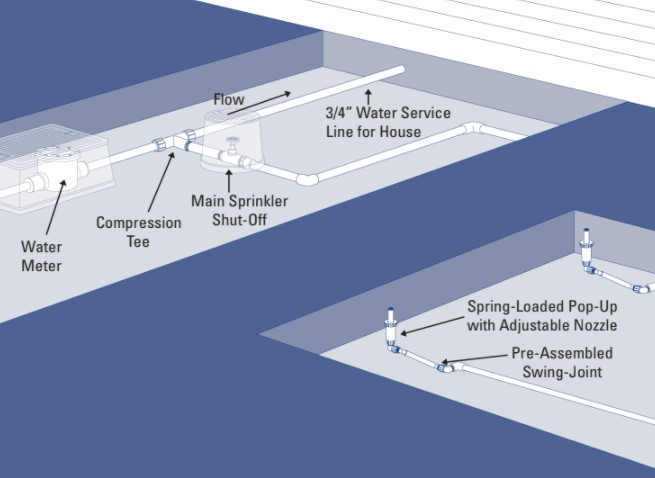

The Main Sprinkler Shut-Off valve is the valve that shuts off water to the entire sprinkler system. Connection to the main water supply is “downstream” of your water meter. Mark the location on your plan.

Valve Manifold Location

One valve will be used for each zone. Valves that are grouped together are called a manifold.

It’s common to install one manifold in the front yard and one in back.

Mark the Location on Your Plan

Tip: The valve manifold(s) should be installed in an accessible location, away from heavy foot traffic, where it is easy to operate and service. It’s also a good idea to locate the manifold on elevated ground, to avoid water accumulating around the valves.

Plan Backflow Prevention

A backflow prevention device is used to stop foreign material from siphoning back into the main water supply. The local code information you gathered from your water district should include the type of device to install and where and how it should be installed. Plan a location for your backflow prevention device and draw it on your layout.

Three common types

Note: For certain Canadian areas Dual Check Valves are used

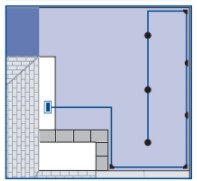

DIAGRAM PIPE LAYOUT

You need to plan and draw the layout for your main sprinkler line and lines for each zone.

Main Sprinkler Line

Draw the Main Sprinkler Line Route

Use a direct route to draw the main sprinkler line from the main shut-off valve to the front and back yard manifolds.

Important: Your main sprinkler line should be 1 size larger than the water main supply line.

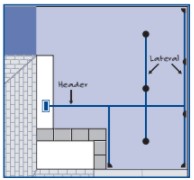

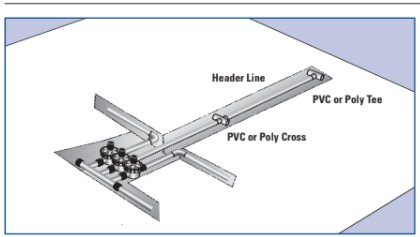

Header and Lateral Lines Guidelines

Header lines — Attaches to a valve and supplies water to the lateral lines

- Do not use pipe smaller than 1″

- Do not attach sprinklers to this line

Lateral lines — Pipe that branches off from the header line and supply water to the sprinkler heads

- Do not use pipe smaller than 3/4″

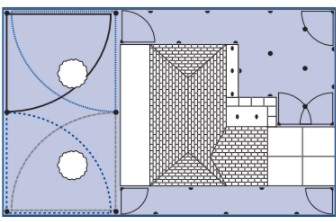

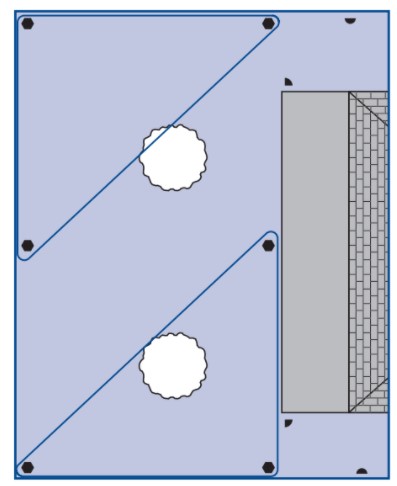

Good Layout Example

This is a good layout because the water is evenly distributed between the lateral lines and individual sprinklers.

Bad Layout Example

Header Line

Draw a header line from the manifold to each zone. Header lines will be intersected with lateral lines.

Sprinkler heads should not be installed on this line.

Use 1″ Pipe

Lateral Lines

Draw lateral lines that connect the header line to sprinkler heads.

These lines should be branching, not circular.

Use 3/4″ pipe

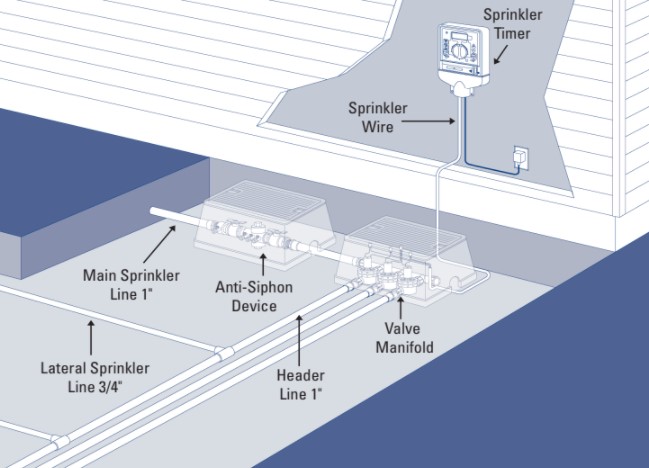

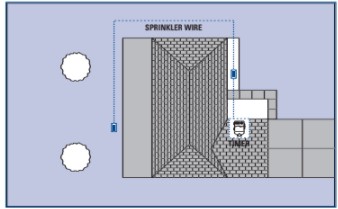

PLAN TIMER LOCATION

Select a location near a power source and where it’s easy to access. You’ll need to be able to run sprinkler wire to each valve. If you select a location outside, the timer should be made for outdoor mounting or protected with a weather resistant box.

Timer Placement & Sprinkler Wire Route

- Mark the planned location for the sprinkler timer

- Draw the route the sprinkler wire will use to connect the timer to the front and rear manifolds

System Layout

Graph Paper

Helpful Tools

Planning

- 50′ or 100′ Tape Measure

- Compass

- Pencil Ruler

- Orbit Pressure Gauge

- String

Layout Graph Paper

Installing Your Sprinkler System

Helpful Tools

Installation

Ground Paint

- Orbit Sprinkler Flags

- Shovel

- Orbit Pipe Cutting Tool

- Screw Driver

- Adjustable Pliers

- Pipe Wrench

- Hacksaw

- Wire Cutter/Striper

- Thread Seal Tape

Installation

This section will show you how to install your sprinkler system.

SYSTEM LAYOUT

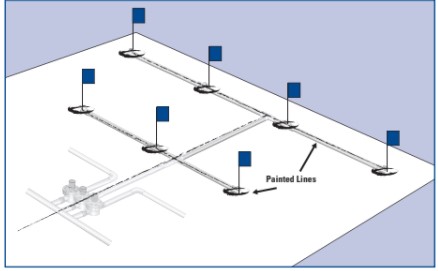

Marking Head and Pipe Location

Begin by marking the entire layout

- Use Orbit sprinkler flags to mark each head.

- Use ground paint to Painted Lines .mark where sprinkler pipes will run.

Important:

- Refer to your local code information for any regulations about connecting to the water main.

- Before digging, contact utility companies and have them mark utility lines.

- Obtain permits (if required).

- Always use gloves and safety goggles when installing.

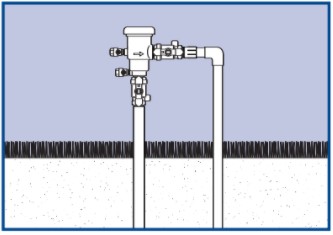

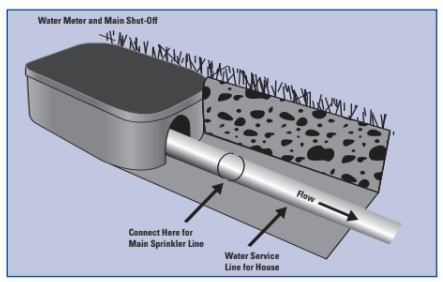

CONNECT TO WATER MAIN

Dig Access Hole

1. Dig to expose the water service line (downstream from the meter).

2. Shut off the main water supply (located next to the meter).

3. Open a faucet to relieve pressure

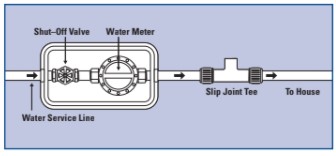

Connect to Main Line

Install a Slip Compression Tee

- Clean off the water service pipe (downstream from meter).

- Cut out a section of pipe — half the length of the tee.

- Install nuts and washers on each Water Service Line side of the pipe.

- Insert the slip joint tee and tighten the nuts with a wrench.

Shut-Off Valve – Non-Freezing Area

Install a Gate or Ball valve after the tee and cover it with an Orbit® valve box to protect it and for easy access to the valve.

- Use fittings to install a Gate or Ball valve on the tee.

- Turn on water to flush line of debris.

- Cover with an Orbit valve box.

Important: Frost Areas or Basement Located Water Meters

Do not use the example above if you are connecting to a water supply line that is located in an area with freezing temperatures or a line that has a water meter located in the basement.

For help in making the proper connections go to www.orbitonline.com for detailed recommendations or contact your home improvement center.

BACKFLOW PREVENTION

Install a back-flow prevention device (if required). Use local code information to determine:

- What type of device is required

- How it needs to be installed

- Who is authorized to install it

DIG TRENCHES

Using the painted lines as your guide (see System Layout, Page 13) dig trenches to the depth required by local codes.

Important: Refer to your local codes to determine how deep your header and lateral lines need to be. Always contact your local utility companies before digging.

Methods for Digging Trenches

- By Hand – Ideal for soft soils and very small jobs

- With Trenching Machine – Available at equipment rental dealers

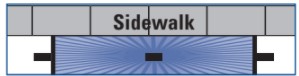

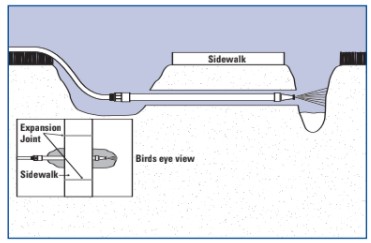

Under Driveways and Sidewalks

Use an Orbit Walkway Tunnel Kit (part # 53333, 91129) to tunnel under obstacles.

- Dig a trench on both sides.

- Attach a garden hose to the tunneling pipe.

- Turn on the garden hose faucet.

- Work the pipe back and forth, allowing the water spray to form a tunnel.

WORKING WITH PIPE

Decide whether you’ll use PVC or Polyethylene pipe for your system. Both types are easy to use, but they are assembled differently. Read about each type below to make your selection.

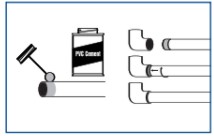

Working with PVC Pipe

- Using an Orbit cutting tool, cut pipe to length and clean the end.

- Apply PVC primer and PVC cement, using instructions provided.

- Insert pipe into fitting.

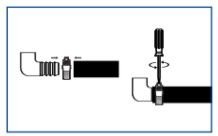

Working with Polyethylene Pipe

- Using an Orbit cutting tool, cut poly-pipe to length.

- Slide a stainless steel clamp over the end of the pipe.

- Insert a barbed fitting into the pipe.

- Tighten the clamp over the pipe and fitting.

Warning: Poly pipe should not be used for the main line to the manifold.

7. INSTALL MAIN LINE

Use PVC schedule 40 (or other pressure-rated pipe) to connect the main shut-off valve to the valve manifold(s).

Important: Use pipe one size larger than your supply line. Using pipe smaller than the main supply line will reduce your water flow and will lead to gaps in spray coverage (For example, use 1″ pipe if your supply line is 3/4″)

Installing main line pressure-rated pipe to front and back manifold

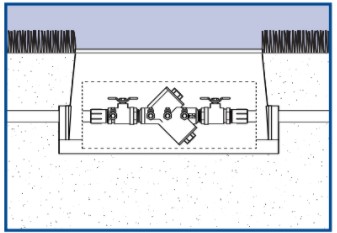

8. INSTALL MANIFOLD

The easiest way to install a manifold is with an Orbit Pre-Assembled Manifold. Purchase a manifold with one valve for each sprinkler zone.

- Installs in minutes

- Works with both Poly-Pipe and PVC Systems

- Cost effective

- Expandable for future sprinkler additions

Note: Anti-siphon pre-assembled manifolds are available for areas requiring use of an anti-siphon valve

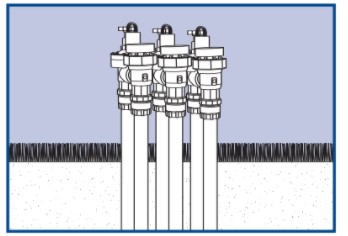

Pre-Assembled Manifold

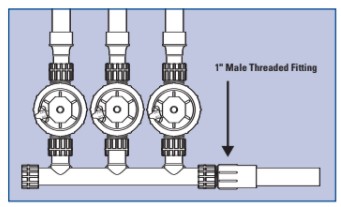

Connecting the Manifold to the Main Line

.

- Before connecting the manifold, open the main shut-off valve to flush dirt from the main sprinkler line.

- Connect the Pre-Assembled Manifold to the main sprinkler line using a 1″ threaded fitting.

9. CONNECT ZONES

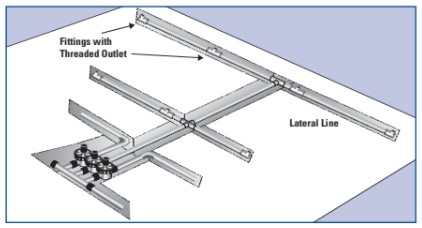

Install Header Lines

- Connect 1″ pipe to each valve and run it to the assigned zone.

- Use fittings (elbow, cross or tee) for each

Install Lateral Lines

- Connect 3/4″ lateral lines to the header line.

- Run lateral line to each sprinkler location.

- Install Tees or Elbow at each sprinkler location.

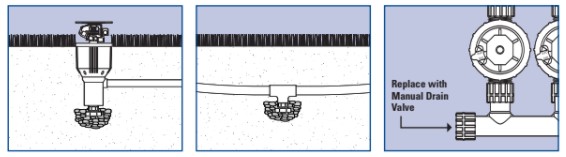

Freezing areas –install line drains

Lateral and Header Lines

Canister Heads: Install an automatic drain valve in the bottom inlet of all canisters.

End of Sprinkler Line: Install an automatic drain valve after the last head on the end of each sloped line.

Low Spots: Install a tee and automatic drain valve for low spots on sprinkler head lines.

Main Line

Manifold: Remove the end cap and install a ball or gate manual drain valve.

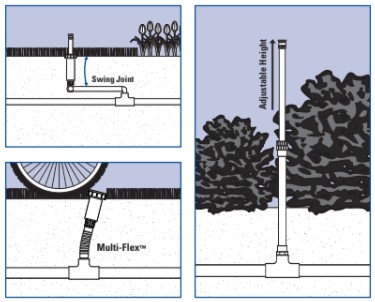

10. INSTALL RISERS & HEADS

Install Risers (Without Heads)

Risers are designed to bring the sprinkler head up to ground height. A wide selection of risers are available. Select the riser that best fits your needs.

Swing Joints & Riser Flex

- Easy to adjust sprinkler height

- Resists impact and cracking

- Useful for placing heads in hard to reach areas

Multi-Flex” Risers

- Comes in various lengths

- Deflects impact

Aluminum Riser with Adjustable Nozzle

- Adjusts in Height as Plant Grows – 16″ to 30″

- Easy Pattern Adjustment — 25° to 360°

Flush Sprinkler Lines — Prior to Installing Heads

- Ensure PVC glue has dried adequately.

- Turn on the main line sprinkler valve.

- Manually turn on one valve at a time (see valve instruction booklet).

- Run each valve for a few minutes.

Installing Heads and Testing

- Attach sprinkler heads to each riser and adjust the height to proper level.

- Place enough soil in the trench to stabilize heads but don’t fill the trench.

- Manually turn on one valve at a time.

- Check for leaks.

Important: Adjust heads for proper spray pattern and check for adequate head to head coverage.

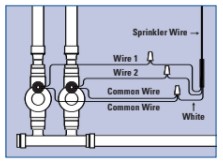

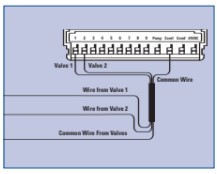

11. CONNECTING SPRINKLER WIRE

Sprinkler wire consists of one white (common) and 4 or 6 colored strands. The sprinkler wire needs to have at least one more wire strand than the number of valves being installed.

Wiring the Valves

Using wire nuts and grease caps connect the wires as shown:

- Connect one wire from each valve to the white (common) sprinkler wire.

- Connect the 2nd wire from each valve to a separate color wire.

Tip: Orbit’s Pre-Assembled Manifold with Snap-Wire Connection makes wiring valves easy. Just plug in the valve jack into the water-tight Snap-Wire housing and insert sprinkler wire into the other side. No confusing wiring or messy grease caps (see page 22 for more info).

Run Sprinkler Wires to Timer

Most often you can use an existing sprinkler pipe trench to run your sprinkler wire. In areas of frequent digging, a conduit pipe is used to protect the wire.

Wiring Your Sprinkler Timer

- Unplug your timer from the power source (if hard wired turn off appropriate breaker switch or remove fuse).

- Connect each colored sprinkler wire to a separate numbered terminal (on the timer).

- Connect the white (common) wire to the common terminal on the timer.

- Restore power to your timer.

- To test proper wiring, manually run each station from the timer.

BURYING SPRINKLER PIPE AND VALVES

Before Burying Trenches:

1. Check all fittings, heads and valves for leaks.

2. Adjust sprinkler height to proper level.

3. Adjust each head for proper spray pattern and spray distance. (Use your drawings as a reference.)

4. cover manifolds with an orbit valve box

APPENDIX

Chart 1

| Gear drive | 30 PSI | 40 PSI | 50 PSI | 60 PSI | 70 PSI | 80 PSI |

| Voyager II | 1 | 2 | 2 | 3 | 4 | 4 |

| Saturn II | 2 | 2 | 3 | 4 | 5 | 5 |

| Impact sprinklers | ||||||

| Satellite | 1 | 2 | 2 | 3 | 4 | 4 |

| ½ brass | 1 | 1 | 2 | 2 | 3 | 4 |

| Pop up and shrub spray head | ||||||

| Adjustable and fixed | 4 | 5 | 6 | 7 | 8 | 9 |

| Strip pattern | 3 | 4 | 4 | 6 | 7 | 8 |

| Shrub bubbler | ||||||

| Mushroom bubbler | 4 | 6 | 8 | 10 | 13 | 15 |

| Gear drive | 30 PSI | 40 PSI | 50 PSI | 60 PSI | 70 PSI | 80 PSI |

| Voyager II | 2 | 2 | 3 | 4 | 5 | 6 |

| Saturn II | 3 | 3 | 4 | 5 | 6 | 7 |

| Impact sprinkler | ||||||

| Satellite | 2 | 2 | 3 | 4 | 5 | 6 |

| ½ brass | 1 | 1 | 2 | 3 | 4 | 5 |

| Pop up and shrub spray head | ||||||

| Adjustable and fixed | 4 | 5 | 7 | 9 | 10 | 12 |

| Strip pattern | 3 | 4 | 5 | 7 | 9 | 10 |

| Shrub bubbler |

* With pre-installed nozzle

** Based on an average flow rate of 1.6 GPM per head

*** Adjustment set below 1/2 flow

Important: These figures are based on a typical sprinkler system.

Before burying sprinkler pipe, run each zone to confirm adequate spray coverage

Chart 2

Gear drives

| Voyager II | 20-40 |

| Saturn II | 15-30 |

| Impact sprinklers | |

| Satellite | 20-40 |

| ½ brass impact | 25-45 |

| Medium area sprinklers | |

| Pop ups | |

| Adjustable nozzle | 10-15 |

| Fixed nozzle | 10-15 |

| Shrub and flower | |

| Bubbler | Spot |

* Spray distance adjusted by diffuser pin

Important: Before burying sprinklers, check for head to head spray coverage. Adjust if necessary.

.

Chart 3

| Voyager II POP UP GEAR DRIVE HEAD | |||||

| NOZZLES | 30 PSI | 40 PSI | 50 PSI | 60 PSI | 70 PSI |

| 1 | 5 | 6 | 7 | 8 | |

| 2 | 7 | 8 | 9 | 10 | |

| 3 | 9 | 10 | 12 | 13 | |

| 4 | 12 | 14 | 16 | 18 | |

| 5 | 16 | 18 | 20 | 22 | |

| 6 | 20 | 24 | 27 | 29 | |

| 7 | 25 | 30 | 34 | 37 | |

| 8 | 32 | 37 | 42 | 46 | |

| 9 | 42 | 49 | 55 | 60 | |

| 10 | 60 | 68 | 76 | 82 | |

| 11 | 80 | 89 | 98 | 105 | |

| 12 | 114 | 122 | 132 | 144 |

* Factory installed 7″ nozzle

Spacing 20’ – 45”

SELECTING THE BEST COMPONENTS FOR YOUR SPRINKLER SYSTEM

Sprinkler Timers

The timer is the brains for your underground sprinkler system that controls when and how long to irrigate your yard. Orbit’s line of timers are known for reliability, ease of installation, programming simplicity and a 6 year warranty, making Orbit Timers the #1 choice by homeowners.

Slide Switch

The easiest timer to program, with water saving features

- Large Display with Text Messaging – Easy to program, easy to use

- 3 Independent Programs – Days of Week, Watering Intervals and Odd/Even Days

- Water Saving Features — Water Budgeting, Rain Delay & Rain Sensor ports

- Slide Switch Feature — One-Touch sliding bar adjusts each station watering duration. Ideal for lawn and micro-irrigation.

- Pump or Master Valve Feature

Super Dial

- Large Dial and Buttons — Simplify programming

- 2 Independent Program — Days of Week, Watering Intervals and Odd/Even Days

- Rain Delay – Settings for 24, 48 and 72 hours

- Screw-Less Terminals — No tools required

- Pump or Master Valve Feature

- Up to 8 Start Times Per Day — Ideal for new lawn and reducing run-off

Dual Program

- Easy to Program

- 2 independent programs — Days of the week and Watering intervals

- Water-Saving Rain Delay Feature — Settings for 24, 48, and 72 hours

- Up to 8 Start Times Per Day — Ideal for new lawn and reducing run-off

Dual Program With Wireless Remote

Same features as the Dual Program timer with the addition of Wireless Remote

- Time Saver – Ideal for installation, testing, maintenance, and sprinkler adjustments

- Allows Operation of Individual Stations — Up to 200 feet

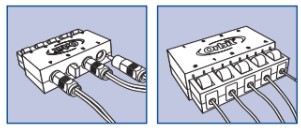

Pre-Assembled Valve Manifolds

Orbit valves continue to set a high standard for solid construction and reliability.

Pre-Assembled Manifolds with Snap-Wire”

- The most complete and reliable multi-valve system

- Installs in minutes

- Snap-Wire” plug-in system simplifies wiring

- Works with PVC or Poly-Pipe

- 6 Year Warranty

Available:

- Standard Inline – 2 and 3 valves

- Anti-Siphon – 2 valves

Spring-Loaded Pop-Ups with Adjustable Nozzle

Standard Top —The standard plastic cap with an adjustable nozzle offers convenience, ease and value for the homeowner. “Just set and forget.”

Soft Top” —The Soft Top adds a soft cushioned rubberized cap.

Hard Top —The Hard Top adds a metal cap for high traffic areas, such as driveways and sidewalks, where sprinklers are subject to contact with vehicles and yard equipment.

Features

- Easy to Adjust Spray Pattern — 25° to 360°

- Spacing – 10′ to 15′

- Available in 2″ and 4″ Pop-Up Height

- 5 Year Warranty

Voyager Il & Saturn III Gear Drives

The #1 Choice by Homeowners

- Simple Pattern Adjustment — 40° to 360°

- 4″ Pop-Up Height — Clears long grass

- Easy to Adjust Spray Distance – 20′ to 40′ Voyager II, 15′ to 30′ Saturn III

- Quiet and Smooth Rotating Spray

- 5 Year Warranty — Dependable and trouble-free performance

- Additional Nozzle Sizes Available — 20 for Voyager II and 3 for Saturn III

Orbit valve box

Durable long lasting construction

Available:

- 20″ Jumbo Rectangle Box

- 12″ Standard Rectangle Box

- 10″ Round Box

- 6″ Round Box

- 32″ to 54″ Adjustable Curb Box

READ ALSO: ORBIT SPRINKLER MANUAL TIMER QUICK START GUIDE

PARTS LIST

| Automatic timers and pump relay | ||

| part | Description | quantity |

| 6 station slide switch | ||

| 12 station slide switch | ||

| 6 station super dial | ||

| 9 station super dial | ||

| 6 station wireless remote | ||

| 4 station dual program | ||

| Pump start relay | ||

| Preassembled manifolds | ||

| Inline | ||

| 2 valve with snap wire connection | ||

| 57150 | 3 valve with snap connection | |

| 57153 | ||

| Anti -siphon | ||

| 57172 | 2 valve anti -siphon | |

| Automatic valve | ||

| Inline | ||

| 57467 | 1 male threaded jar top | |

| 57461 | 1 female threaded jar top | |

| 57100 | 3/4 threaded | |

| 57101 | 1 threaded | |

| Anti-siphon | ||

| 57623 | ¾ anti- siphon threaded | |

| 57624 | 1 anti- siphon threaded | |

| Backflow valve | ||

| 51050 | ¾ double check valve | |

| 51057 | ¾ pressure vacuum breaker | |

| Valve boxes | ||

| 53210 | 6 circular | |

| 53211 | 10 circular | |

| 53212 | 12 standard rectangle | |

| 53029 | 32-54 adjustable curb box | |

| Tools | ||

| 53020 | Orbit pressure gauge | |

| 26085 | Pipe cutting tool | |

| 53326 | Sprinkler flags | |

| 53333 | Walk away tunnel kit | |

| Accessories | ||

| 51040 | ½ plastic automatic drain valve | |

| 53266 | 28” curb key | |

| 53034 | 5” steel curb key | |

| Sprinkler wire | ||

| 57088 | 7 conductor 100-for up to 6 valves | |

| 57093 | 5 conductor 100 for up to 4 valves | |

| Sprinklers | ||

| Large area | ||

| 55060/55061 | Voyager II gear drive | |

| 55059/55069 | Saturn II gear drive | |

| 55012 | Satellite pop up impact | |

| Medium area spring loaded pop ups | ||

| Spring loaded pop up /adjustable pattern | ||

| 54115 | 2 hard top | |

| 54118 | 4” hard top | |

| 54113 | 2” soft top | |

| 54114 | 4” soft top | |

| 54116 | 2” standard | |

| 54117 | 4” standard | |

| Spring loaded pop up /fixed pattern | ||

| 54016 | 2” full pattern | |

| 54017 | 2” half pattern | |

| 54018 | 2” quarter pattern | |

| 54127 | 2” center strip | |

| Small area | ||

| 54042 | Mushroom breaker | |

| 37330 | Aluminum riser 16 to 30 adjustable nozzle | |

| Riser flex and swing joints | ||

| 37264 | ½ x1/2 x12 pre- assembled swing joint | |

| 37265 | ¾ x1/2 x12 preassembled swing joint | |

| 37163 | ½ male x female swing joint | |

| 37164 | ¾ male x female swing joint | |

| 37159 | ½ male x1/2 barb elbow riser flex | |

| 37162 | ¾ male x barb elbow riser flex | |

| 37154 | ½ x 50 riser flex pipe | |

| Multi flex riser and cut off riser | ||

| 37112 | ½ x 6 multi flex | |

| 37069/38500 | ½ x 6 cut off |